Air Cooled Heat Exchanger (ACHE): Insights

Heat exchangers are important equipment in different industries processes because they provide with an efficient method of transferring heat between two fluids without blending them. One type of heat exchanger is an air cooled heat exchanger (ACHE) which uses air as the cooling medium instead of water like other exchangers do. ACHEs have become an integral part of industrial applications because of their water-saving features, lower operational costs, reliable cooling under different environmental conditions, and steady cooling capabilities. This article will discuss the basic principles, components, types, design considerations, advantages, applications, challenges, and future trends concerning air cooled heat exchangers.

Introduction To Air Cooled Heat Exchangers

As with other heat exchangers, air cooled heat exchanger systems are designed strategically to transfer heat from a hot fluid to surround air by flowing through a system of finned tubes. Air is blown over the fins located on the tubes, and a hot fluid flows through the tubes. As the air passes over the fins, its surface area is increased, enhancing the transfer of heat. The fluid is cooled as heat is absorbed from it by air. Temperature of the air also increases during the process, and as a result, the fluid inside the tubes cools and continues to circulate.

We can find air cooled heat exchangers in the following industries: petrochemicals, refrigeration, power generation, and HVAC systems.

These systems provide a substitute for heat exchangers that use water as a coolant, and are particularly advantageous where water is scarce or where there are stringent environmental regulations against its use.

Working Principle of Air Cooled Heat Exchangers

The working principle of air cooled heat exchangers is based on the principle of removing heat through a fluid which carries the heat from the tubes to the air surrounding it. Heat transfer in ACHEs occurs through three primary mechanisms which are conduction, convection, and radiation.

Heat conduction is the first mechanism and takes place when heat is transferred from the fluid located in the tubes to the metal walls of the tubes. This heat transfer process is quite effective because the fluid is at a higher temperature than the surroundings.

The air’s movement also influences temperature transfer, which is represented in the movement of warming air and takes place at the surface of the tube with water which is warmer than the air. The tube’s temperature and the temperature of materials are not strongly related. The convection heats the surface of the tubes and as soon the air is heated to the proper temperature it leaves the vicinity of the tubes. The rate of convection: air circulation speed above the tubes and temperature difference between air fluid, what enhances chances of fluid in the pipes seems much poorer.

Alongside these two mechanisms, a minor temperature change in heat transfer can also be caused by radiation.

Although radiation is often less important than convection for ACHEs, some heat is radiated from the tube surfaces and fins to the environment.

An air cooled heat exchanger (ACHE) has a lower efficiency rank as it may contain high temperature fluids, and the surrounding air temperature might not be as hot. Further, the efficiency also depends on the areas of the tubes, the airflow direction, and even the wind speed. The heat exchange processes can be improved by the design parameters of heat exchangers like the quantity of the blades and types of fans used.

Key Components of Air Cooled Heat Exchangers

The fan, frame, shell, and motor, along with other elements, make a complete set of air cooled heat exchangers that improve heat transfer and system efficiency. Every component mentioned is crucial to maintaining the airflow and heat transfer rate, and operate together to ensure smooth functionality.

Every air cooled heat exchanger has to have tubes attached to their fins, for they serve as the main sides where heat is exchanged. These tubes need to be made of good thermal conductivity metals like copper or aluminum. To maximize the heat transfer process, increased surface area should be achieved through fins attached to the tubes. So, better area coverage means improvement in the rate of heat dissipation. Thus, more and better covered increased area finned tubes serve heavier proportions of cooling. So, stronger increased surface area leads to stronger heat dissipation. So, good and copious enhanced area finned tubes provide strong cooling.

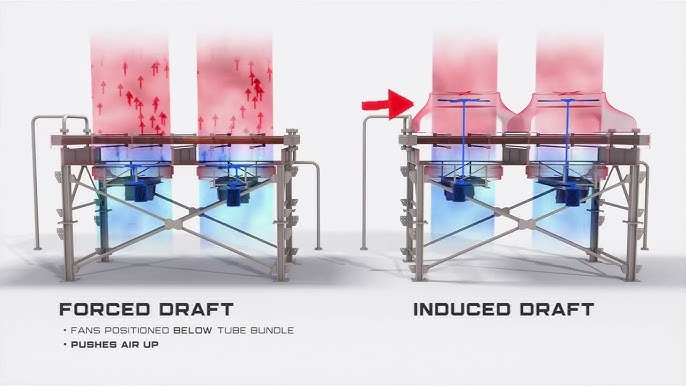

Moving air across the finned tubes would be impossible without applying fans; hence, they are vital for air circulation.

The airflow from the fans assists in removing the heat that has been absorbed by the air. There are two primary types of fans that are used in ACHEs: axial fans and centrifugal fans. Probably due to their ability to handle large volumes of air efficiently, axial fans are the most common type used in ACHEs.

The frame and shell constitute the physical parts of the heat exchanger. The frame houses the tubes, fans, and other components while the shell contains the tubes and makes sure fluid and air are separated. The shell is meant to channel the air over the finned surfaces and prevent blending of the fluid inside the tubes with the air.

Different arrangements of air and fluid flow can exist with respect to the direction the fluid flows inside the tubes. A few arrangements are: parallel flow, counterflow, and crossflow. In parallel flow, both the air and fluid flow together, and in counterflow, they move in opposite directions. Counterflow arrangements are the most efficient because of a higher temperature difference between the fluid and air. Crossflow arrangements are a good compromise between efficient heat transfer and saving space.

Fan speed can be adjusted based on the heat load since motors powering the fans are capable of speed control.

Integrating fans with variable speed drives (VSDs) makes it possible for fans to function at speeds commensurate with the level of cooling needed, thus saving energy.

Categories of Air Cooled Heat Exchangers

Various types of air cooled heat exchangers are designed to meet specific application requirements based on the nature of work and operating conditions.

Single-phase air cooled heat exchangers serve a system in which the operating fluid is exclusively a single phase—liquid or gas. The fluid’s temperature remains constant and no phase changes occur thermodynamically during cooling. This type is often used in industrial systems for cooling lubricating oils, water, and gases.

Conversely, two-phase air cooled heat exchangers are meant for fluids that can exhibit phase transitions such as refrigerants in air conditioning and refrigeration systems. Their complexity compared to single-phase systems stems from their need to handle fluid phase change: liquid-vapor or vapor-liquid transition.

Air cooled heat exchangers with finned tubes are specialized air cooled heat exchangers where a set of metal fins is placed along the heat transfer tubes to enhance the surface area for heat transfer.These exchangers can be found in industries like petrochemical processing, power generation, or chemical manufacturing. The fin fan heat exchanger type offers high efficiency in transferring heat and is suitable for high heat load conditions.

Compared to traditional air cooled heat exchangers, compact air cooled heat exchangers are more compact. They are ideal for mobile uses like offshore platforms or facilities, which have limited space.

In Air Cooled Heat Exchangers, what should be kept in mind?

Air cooled heat exchangers need to take many factors into account when being designed. These are the heat load, the fluids, the air surrounding the unit, the airflow, chosen materials of the unit, and space for the unit.

In the case of ACHEs, the heat load which could also be referred to as the amount of heat that needs to be removed from the heated fluid in most cases is one of the key deciding factors. It is important that the heat exchanger is able to handle the maximum heat load during operation. The fluid’s factors must include its depreciation and how viscid or its thermal conductivity and specific heat, because lower performance would lead to lower heat transfer.

Surrounding air temperature and humidity are also very important when considering the performance of the heat exchanger.

In areas with high ambient temperatures, Cooling efficiency might not perform at full capacity. So, it is important to find a heat exchanger that works proficiently under these circumstances. In addition, the airflow rate must handle excessive heat as the bare minimum in order to mitigate pressure drop and unnecessary energy usage.

Selection of materials is just as critical. The tubes, fins or any other parts must possess enduring strength and be immune to corrosion, particularly in open air settings. Some of the ACHEs use stainless steel, aluminum and copper due to their assets of good thermal conductivity and resistance to corrosion.

The offered design should consider space restrictions for installation too. While compact designs are helpful in tighter additional spatial constraints, they must not compromise on offering a required surface area for heat transfer. Besides, the system should be easy to maintain to support the regular cleaning of fins and tubes to clear the too much dust and debris build up.

Benefits of Air Cooled Heat Exchangers

Water cooled systems have their own benefits, however air cooled heat exchangers are certainly more advantageous. One of the major advantages of air cooled systems is saving water.

Since ACHEs do not require water, they are well suited for areas of water scarce regions as well as industries attempting to conserve water for environmental reasons. These industries are particularly useful in gas and power industries, which usually face the problem of water scarcity.

Reduction of operational cost is another benefit.ACHEs eliminate the need for cooling water, which is costly in water cooled systems. The absence of water treatment systems and infrastructure further lowers both the construction and upkeep costs.

Air cooled heat exchangers are also more environmentally friendly than water-coolers. Unlike water-based systems, ACHEs do not generate wastewater or require anti-corrosion chemicals, which lowers the risk of contaminating the environment.

Moreover, under specific conditions, ACHEs may be more energy efficient. If variable speed drives are employed, airflow can be modified to meet cooling demand, improving efficiency. In general, ACHEs tend to consume less energy than water cooled systems because they lack pumps and circulation systems.

Water cooled systems have a higher maintenance demand compared to ACHEs.

Water cooling systems have continuous scaling, fouling, and corrosion issues that require higher maintenance. On the other hand, ACHEs need maintenance only to clean dust and debris, making them easier, less costly, and more efficient.

Applications of Air Cooled Heat Exchanger

Air Cooled Heat Exchangers (ACHE) find application in almost every industry due to their availability and ease of use. This includes the petrochemical HVAC systems, power generation, natural gas processing, refrigeration, and construction.

In the petrochemical industry, hot process fluids and gases need to be cooled using ACHEs. These exchangers are beneficial for offshore platforms because of the high demand for cooling fluids and a low supply of water. In power plants, ACHEs are also commonly used for turbine exhaust gas and other high-temperature fluid cooling.

In HVAC systems, ACHEs are used for refrigerant and air-condtioning system cooling. These are deployed in large commercial and industrial facilities where water cooling is not an option. In natural gas processing, ACHE are used to cool gas streams while maintaining temperature control during the extraction and processing phases.

Air Cooled Heat Exchangers are also widely used in the refrigeration and freezing industries.

They serve the purpose of cooling the refrigerants in industrial refrigeration systems, large freezers, and cold storage facilities.

Problems and Restriction of Air Cooled Heat Exchangers

Although air cooled heat exchangers have numerous benefits, they still face problems. One problem is their efficiency in hotter ambient temperatures. When the temperature of the ambient air becomes hot and approaches the temperature of the fluid to be cooled, the heat transfer efficiency drops. This poses ACHEs challenges in warmer regions or in situations with greater cooling needs.

Another problem is the space occupied by large air cooled heat exchangers. While there are compact models, some industries cannot afford to spare the real estate taken by the larger systems. Also, fans associated with ACHEs pose other problems as their operation generates considerable noise adding to the challenges in areas requiring quiet operations.

Environmental challenges like dust and debris as well as severe winds can degrade the functioning of air cooled heat exchangers. In dusty environments, the fins and tubes get clogged leading to reduced cooling. Also accompanied with heavy snow, rain can impair system performance, demanding greater protective measures.

Final Thoughts

Industrial sectors relying on sophisticated operational plants rely on cooling systems that have air cooled heat exchangers.

They offer numerous benefits such as conserving water, lowering operational costs, and having a reduced environmental impact. Though facing challenges like decreased efficiency at elevated ambient temperatures and spatial constraints, air cooled heat exchangers are still one of the most dependable and green solutions available today. As businesses focus more on environmental friendliness, ACHEs are expected to provide more sustainable and economically viable cooling alternatives.