Due to the dynamic shifts within the cannabis sector, it has become imperative to nadel an infused pre-roll with a specific quality alongside meeting infusion and geographic regulations. Crucial compliance mandates such as quality assurance deliverance have become increasingly vital for business sustainability within the cannabis industry—or rather for any industry. With growing demand, user dosing accuracy and microbial contamination have emerged as serious issues. Deficiencies can lead to costly violation regulation penalties, extreme loss of clientele, or reputation damage. On the other hand, uncontrolled methods of infusion face dire consequences trying to keep pace with growing and ever-evolving market needs. Manual infusion approaches have become obsolete and will no longer merge with harvesting industry standards. This growing need is complemented by in-robot pre-roll infusion automation.

Pre-roll infusion robots are optimizing cannabis cultivation processes unlike any other aid. For every productivity-centered cannabis firm, these instruments return benefits far beyond investment costs. Equipped with compliance and accuracy features, contemporary infusion robots automate cannabis derived product dosing and substance allocation—ensuring consistent fuel efficiency across multiple production scales with the branch’s extensiveness.

The Need for Consistency in Infused Pre-Rolls

Keeping infused cannabis pre-rolls consistent is not only a matter of quality control, but also brand image, legal liability, and customer confidence. Every time a consumer buys a pre-roll, they expect to receive the same experience in terms of potency, burning attributes, and guaranteed effects. Concentrate distribution consistency is crucial as even the slightest discrepancy can drastically change the experience. Overdosing may lead to overpowering effects or failure in third-party testing— a less than optimal scenario. Underdosing, however, will result in unmet expectations, unhappy users, and lackluster performance.

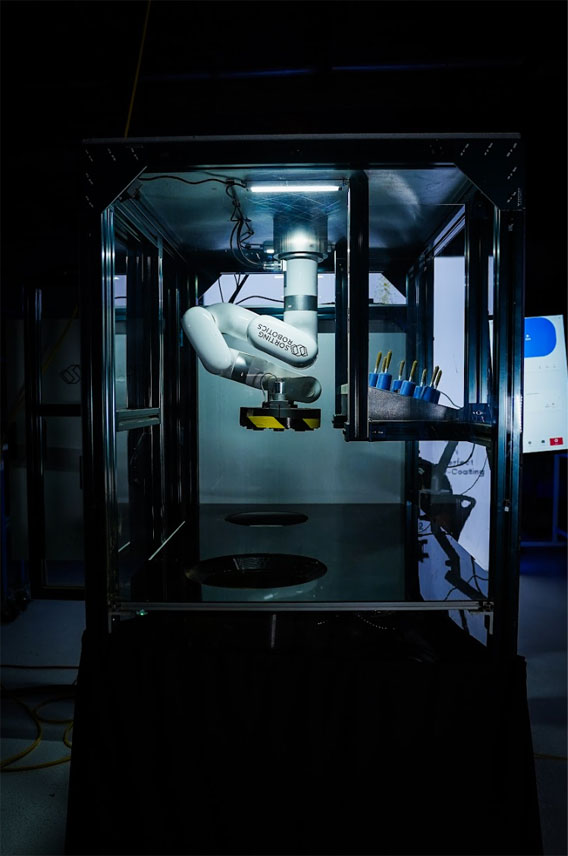

Due to fatigue, errors, or changes in the concentration’s viscosity, manual methods introduce differences in dosage. A technician may under-infuse some joints while overfilling others, resulting in batch inconsistency and increased reject rates. Designed by Sorting Robotics, automated infusion robots infuse entire batches to solve these problems. These machines eliminate the differences that manual processes have by ensuring that each joint receives an exact dose of concentrate correctly placed. These devices have uniform placement which guarantees that sets of joints receive the same amount of concentrate.

How Automation Delivers Precision at Scale

Cannabis manufacturing has being automated to super-charge speed, enhance accuracy and enable repeat processes, thus revolutionizing the whole industry. These infusion pre-roll robots work on precise set parameters such as volumetric infusion, location which needle will be used to put infusion in flower, and flow rate. Advanced infusion extraction systems now use intelligent algorithms with feedback loops for infusion control, monitoring over every single step of the infusion process. Starting from the very first joint in the batch to the very last, dosing consistency is now masterful.

Unlike tedious forms of work that can lead to tiredness and mistakes, robots are able to work unconditionally at any time of day, without diminishing the quality or consistency of their output. An automated system, for instance, is able to infuse up to 1,200 joints per hour, making it possible for producers to complete big orders within short deadlines. Bases Sorting Robotics is a provider of pre-rolled cannabis concentrate systems that alters by set algorithms concentrate types and pre-rolled sizes to maximize efficiency alongside production control while providing uniformity to the cannabis products.

Reducing Human Error and Contamination Risk

In an industry where precision is paramount, one of the most important things that automation does is diminish human error and contamination risk. Human operators, however well-trained they may be, are still liable to measure inconsistently. Manual processes with concentrate syringes and the potential for batch cross-contamination indicate that quality assurance within manual processes is imperfect. This not only jeopardizes consumer safety, but also increases the probability of product recalls.

With few contact points, infusion robots result in a closed-loop process. Closed and controlled handling of cannabis and concentrates is automated. Operators no longer need to measure, inject, or seal infused joints; which are all tedious, intricate processes requiring mental focus—and lots of it. If cannabis manufacturers were to implement automation in pre-roll production, it would be much easier to maintain hygiene, eliminate expensive cross-contamination, and protect the integrity of the product.

Streamlining Regulatory Compliance

Cannabis production is one of the industries with the most stringent governance in the world. Governig authorities expect producers to observe dosaging precision, product cleanliness, cleansing procedures, and thorough documentation during testing processes. Any divergence from these standards would result in sent laboratory tests, penalties, recalls of products, or, in extreme cases, suspension of business licenses. More often than not, these requirements are very challenging to fulfill consistently because processes are manual and volumes of production increase.

Sorting Robotics offers automated infusion systems, which include integrated compliance features. Automated compliance assistance eliminates the need for manual compliance burdens. It simplifies tedious monitoring and record keeping that manually tracked, maintained, and maintained. Only enables accurate and consistent dosing, but also tracks dispensing automation, including digital action registries. Batch details may be entered, output volume monitored and reports that are ready for audits may be exported. Their meticulous record-keeping capabilities bring automation and robotic precision to processes, lessening manual labor and improving efficiency. Through automation, an organization’s achievement can be monitored, controlling resource expenditure, one step at a time. Recognizable information and timely protocols ensure seamless compliance with regulatory frameworks, maintaining lawfulness for procedures. In the light of frequent shifts of tightening of policies, such measures prove advantageous. Changes in these automated systems may be implemented through simple programming, allowing uninterrupted business processes.

Enhancing Brand Reputation and Trust

In a competitive cannabis market, brand reputation can be the difference between thriving and failing. Brands that can reliably produce consistent, high-quality infused pre-rolls will win over retailers, dispensaries, and end consumers. On the other hand, a single inconsistent batch can damage consumer trust and lead to negative reviews or regulatory penalties. Reliability is the backbone of brand loyalty in this space.

Using automated infusion robots enables producers to elevate their product consistency to pharmaceutical-grade levels. Uniform dosage, precise infusion location, and improved shelf stability all contribute to a better consumer experience. Over time, this consistency strengthens the brand’s reputation as a quality leader in the cannabis space. With automation from companies like Sorting Robotics, businesses can position themselves as premium producers, commanding higher price points and developing long-term customer loyalty.

Conclusion

The adoption of automated pre-roll infusion robots is no longer a luxury—it’s a necessity for cannabis producers looking to ensure compliance, consistency, and efficiency at scale. These systems replace unreliable manual methods with precision-driven automation, minimizing risk, cutting costs, and enabling rapid growth. For cannabis companies operating in highly regulated environments, automation provides a powerful safeguard against compliance failures while also enhancing product quality and brand value.

With built-in dosing accuracy, contamination prevention, and digital reporting, these robots offer a long-term solution to some of the most critical challenges in cannabis production. By investing in a solution like the one offered by Sorting Robotics, cannabis brands are not only future-proofing their operations but also laying the groundwork for scalable, sustainable success in a competitive market.

FAQs

Why is consistency important in infused pre-rolls?

Consistency ensures that consumers receive a reliable experience with each use. Uniform potency, flavor, and burn profile build trust, reduce complaints, and support long-term customer loyalty.

How do automated infusion robots reduce compliance risks?

They deliver precise, repeatable dosing and record all batch data automatically. This helps manufacturers meet regulatory standards, avoid test failures, and streamline compliance audits.

Can infusion robots handle different cannabis concentrates?

Yes, top-tier systems such as those from Sorting Robotics are engineered to work with various concentrate types, including distillate, live resin, and rosin. They offer adjustable temperature and pressure settings for optimal performance.

How do automated robots improve production efficiency?

By automating labor-intensive tasks, these robots drastically reduce processing time, eliminate bottlenecks, and increase throughput. A single machine can process up to 1,200 pre-rolls per hour with high accuracy.

Are these robots a good investment for smaller cannabis businesses?

Absolutely. Even small and mid-sized operations benefit from reduced labor costs, fewer compliance issues, and improved product quality—delivering strong ROI and positioning for future growth.