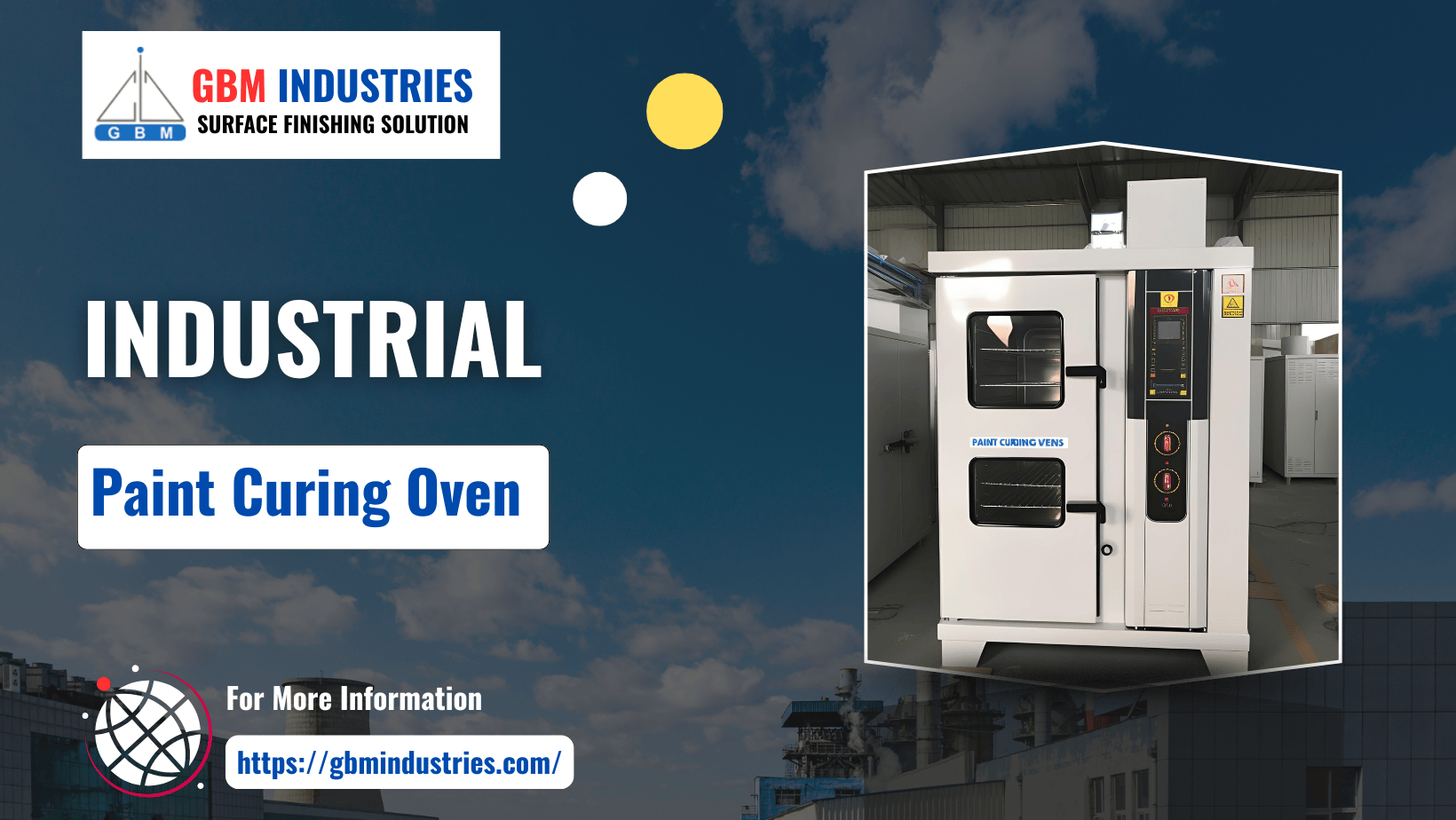

In fast-paced industries where every second and every finish counts, one overlooked hero quietly powers the backbone of quality manufacturing—the paint curing oven. It’s not just a piece of equipment; it’s your key to faster turnaround times, consistent finishes, and long-term cost savings. Whether you’re coating auto parts, metal enclosures, or consumer goods, the way your paint cures can make or break your product’s durability and appeal.

As businesses strive to meet tighter deadlines and stricter quality standards, relying on air-drying or outdated systems just isn’t enough. Paint curing ovens deliver the precision and speed today’s production demands—cutting drying time from hours to minutes while producing a hardened, professional-grade finish every single time.

If your business involves painted components and you’re looking to boost productivity without compromising on quality, this guide will walk you through everything you need to know—from oven types and benefits to smart buying tips and why GBM Industries is the trusted name behind some of the best curing solutions in the market.

What is a Paint Curing Oven?

A paint curing oven is a specialized type of oven used in the industrial paint application process. The oven helps to accelerate the curing (or drying) of paint, ensuring that the paint bonds well with the surface and hardens quickly. By using controlled heat, paint curing ovens make sure that the painted product is durable, resistant to wear, and aesthetically pleasing.

These ovens come in various configurations, including batch ovens, conveyorized systems, and custom-built solutions to meet specific production needs.

Types of Paint Curing Ovens

There are different types of paint curing ovens available, depending on the nature of the products being painted and the scale of production:

- Batch Ovens

Batch ovens are designed for smaller quantities or non-continuous production runs. Products are placed in the oven in batches, and the curing process is carried out for each batch separately. These ovens are ideal for industries with low-to-medium volume production. - Conveyorized Curing Ovens

In contrast, conveyorized curing ovens are designed for high-volume, continuous production lines. Products move through the oven on a conveyor belt, where they are subjected to the required curing conditions. These ovens are typically used in industries such as automotive, metalworking, and manufacturing where large quantities of parts need to be painted and cured simultaneously. - Infrared Curing Ovens

Infrared curing ovens use infrared radiation to heat and cure the paint quickly. These ovens are particularly useful for curing delicate materials that may be sensitive to conventional heating methods, or for applications requiring extremely fast curing times. - Customized Paint Curing Ovens

For specific needs, industries can opt for custom-built ovens. These ovens are tailored to meet particular requirements, such as temperature range, size, or energy efficiency. Custom solutions are ideal for specialized industries that deal with unique materials or have specific curing needs.

How Do Paint Curing Ovens Work?

The curing process involves applying heat to the paint, causing the solvents and additives in the paint to evaporate and the pigments to bond to the surface, forming a durable coating. The paint curing oven uses heat to activate the chemical reactions necessary for this process.

Key steps in the curing process:

- Heating: The oven gradually heats up to the required temperature.

- Thermal Cycling: The painted object is exposed to heat for a set period to allow the chemical reactions to take place.

- Cooling: After the paint has cured, the oven cools down, and the item is removed for further inspection or processing.

Importance of Temperature Control

One of the critical elements of a paint curing oven is its ability to maintain consistent and precise temperature control. Each type of paint has a specific curing temperature range, and the oven must maintain that temperature throughout the process. Too high or too low a temperature can result in poor adhesion, uneven curing, or compromised paint durability.

Many modern curing ovens come equipped with advanced control systems that allow operators to set, monitor, and adjust the temperature precisely. This ensures that every batch or product receives consistent curing, improving the final product’s overall quality.

Key Features of Paint Curing Ovens

To get the best performance from your paint curing oven, look for the following key features:

- Efficient Heating Systems: The oven should have efficient heating methods such as convection, infrared, or a combination of both. This ensures even heating and minimizes energy consumption.

- Temperature Control: Digital or programmable controllers help maintain the exact temperature needed for optimal curing.

- Energy Efficiency: Modern ovens are designed to reduce energy costs by using advanced insulation, energy-efficient heating elements, and heat recovery systems.

- Customizable Sizes: Depending on your production needs, curing ovens can be customized in size to fit the products you’re painting. Whether you’re working with small components or large metal panels, the oven should be capable of accommodating your items.

- User-Friendly Interfaces: A simple control panel or touchscreen interface allows operators to monitor and adjust the settings easily.

Benefits of Using a Paint Curing Oven

Using a paint curing oven provides numerous advantages that can improve both your product quality and production efficiency. Here are some of the key benefits:

- Faster Production Cycle: The use of a curing oven speeds up the drying process compared to air drying, reducing overall production time.

- Consistent Results: With precise temperature control, paint curing ovens ensure consistent and uniform curing across all painted items, resulting in high-quality finishes.

- Enhanced Durability: The heat curing process strengthens the bond between the paint and the surface, improving the finish’s resistance to scratches, chemicals, and environmental factors.

- Better Aesthetics: A well-cured paint finish is more vibrant and aesthetically appealing, providing a smoother and more uniform coating.

- Reduced Downtime: A paint curing oven can be programmed to handle multiple production runs, minimizing downtime between batches and increasing overall throughput.

Industries That Benefit from Paint Curing Ovens

Paint curing ovens are used across various industries that require high-quality painted finishes. Some of the industries that benefit from paint curing ovens include:

- Automotive Industry: Car manufacturers use curing ovens to cure the paint on vehicle parts, ensuring a durable and flawless finish.

- Metal Manufacturing: Industries that produce metal components rely on paint curing ovens to ensure that metal parts are properly coated and resistant to corrosion.

- Consumer Goods Manufacturing: Furniture, home appliances, and other consumer goods are often painted and cured to improve their appearance and durability.

- Electronics Industry: Certain electronic components, such as housings or circuit boards, need to be painted and cured to ensure both functionality and aesthetics.

Client Testimonial

“The paint curing oven from GBM Industries has drastically improved our production speed and product quality. The oven’s precise temperature control ensures that our paint cures uniformly every time, leading to consistent results. It’s efficient, easy to use, and incredibly reliable. We highly recommend it!”

Rating: ⭐⭐⭐⭐⭐ (5/5)

Why Choose GBM Industries for Paint Curing Ovens?

At GBM Industries, we specialize in manufacturing high-performance industrial ovens, including paint curing oven tailored to meet the needs of diverse industries. Our ovens are designed with energy efficiency, durability, and precision in mind, ensuring that you get the best results every time.

Whether you need a batch oven, a conveyorized curing system, or a custom-built solution, we can help you find the perfect oven for your production line. Our team works closely with you to ensure that your specific requirements are met, and we provide comprehensive after-sales support to guarantee the longevity and performance of your equipment.

Final thought

paint curing ovens are an indispensable part of many industrial processes, providing enhanced product quality, faster production cycles, and greater efficiency. At GBM Industries, we are committed to offering top-of-the-line curing ovens that can help improve your production processes. Contact us today to learn more about our industrial oven solutions.