The electronics industry is one of the most innovative and rapidly evolving sectors in the modern world. With continuous advancements in technology and a growing demand for electronic products, manufacturers are always on the lookout for materials that are not only durable and cost-effective but also versatile. One such material that has gained significant popularity is Acrylonitrile Butadiene Styrene (ABS) sheets. ABS is a thermoplastic polymer that is known for its exceptional strength, impact resistance, and ease of molding. In recent years, ABS sheets have become a crucial component in the electronics industry, providing numerous advantages in the production of various electronic devices and components.

1. Durability and Strength

One of the primary advantages of ABS sheets in the electronics industry is their remarkable durability and strength. ABS is known for its ability to withstand high levels of stress and strain, making it ideal for applications where impact resistance is critical. In the electronics industry, where products often undergo rigorous usage and handling, ABS sheets provide a reliable protective casing for devices, ensuring that the internal components are safeguarded against physical damage.

ABS sheets are also resistant to environmental stressors such as UV radiation, moisture, and extreme temperatures. This makes them perfect for electronics used in outdoor environments or those exposed to fluctuating temperatures. Whether it is a mobile phone casing, a laptop housing, or a component in a consumer appliance, ABS sheets provide robust protection, thereby extending the lifespan of electronic products.

2. Excellent Moldability and Customization

Another significant benefit of ABS sheets is their excellent moldability. ABS plastic can be easily molded into complex shapes and forms, allowing for greater flexibility in product design. In the electronics industry, where precision and customization are essential, ABS sheets enable manufacturers to create intricate designs that meet specific functional and aesthetic requirements.

The ease of molding also allows manufacturers to produce parts in bulk with consistent quality. ABS sheets are widely used in the production of housings, covers, and components that require precise specifications. Furthermore, ABS can be easily welded or glued, which enhances its suitability for applications that involve multi-part assemblies.

3. Lightweight and Cost-Effective

When it comes to manufacturing electronics, weight is a critical factor, especially for portable devices such as smartphones, tablets, and laptops. ABS sheets are lightweight compared to other materials such as metals or glass, which helps reduce the overall weight of the final product. This makes them ideal for creating lightweight casings and housings without compromising on durability and strength.

In addition to being lightweight, ABS is also a cost-effective material. ABS sheets are relatively inexpensive to produce, and their ease of processing helps reduce manufacturing costs. This makes ABS sheets an attractive option for electronics manufacturers looking to maintain a balance between quality, performance, and cost-efficiency. As a result, ABS sheets are widely used in the production of electronic products, making them affordable for consumers while maintaining a high level of performance.

4. Thermal and Electrical Insulation Properties

ABS sheets are excellent insulators, both thermally and electrically. This makes them an ideal choice for electronic components that require insulation to prevent heat buildup or electrical interference. For example, ABS is commonly used in the production of electrical enclosures and circuit board housings. The material’s insulation properties ensure that sensitive electronic components are protected from heat and electrical surges, which can otherwise damage or compromise their functionality.

In the electronics industry, overheating is a common concern, particularly in devices that generate significant amounts of heat during operation. ABS sheets help mitigate this risk by providing thermal insulation, ensuring that electronic devices maintain optimal temperature levels and operate efficiently. This is especially important in high-performance devices such as computers, servers, and power supplies, where effective thermal management is crucial.

5. Aesthetic Appeal and Versatility in Design

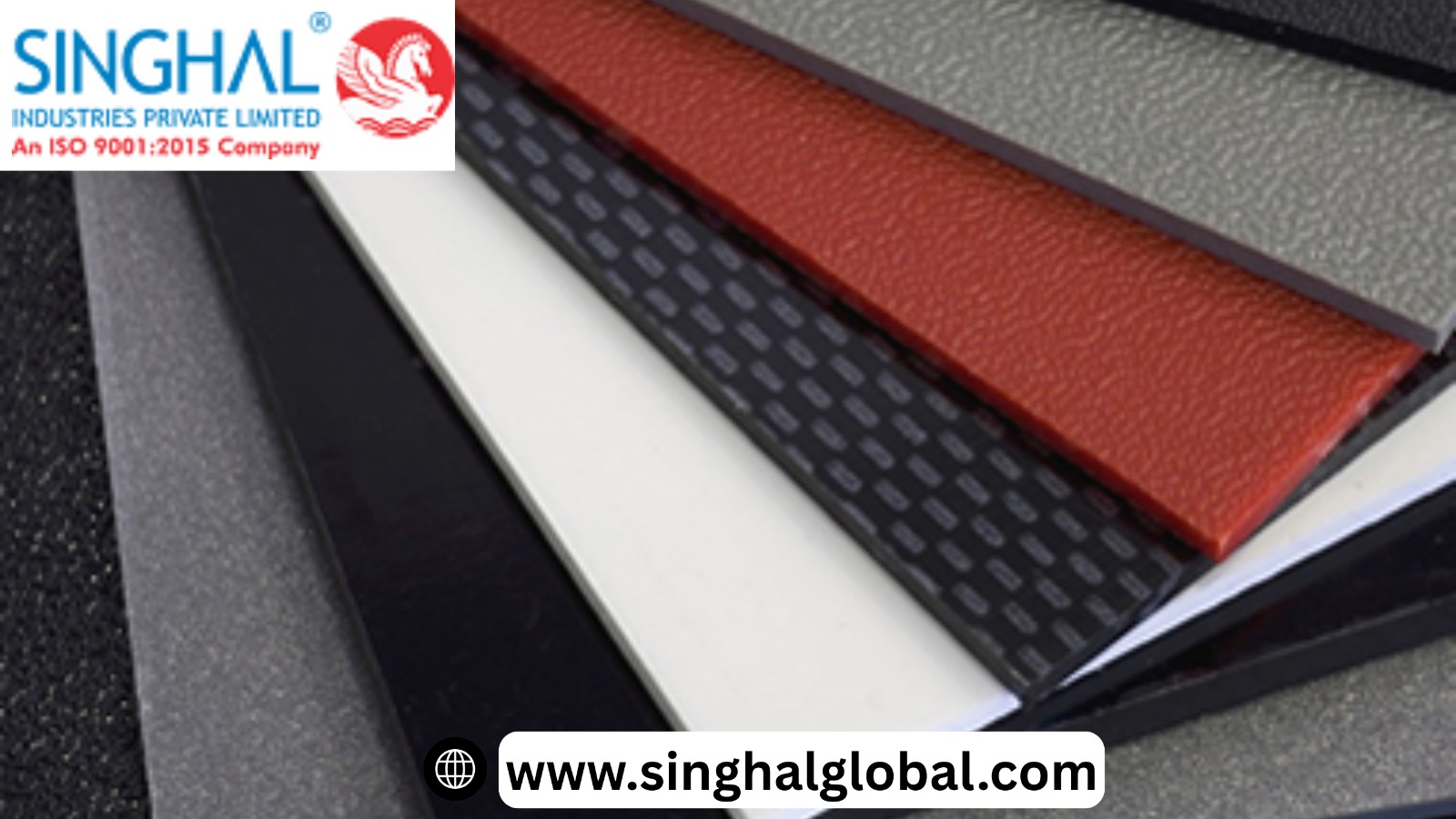

In the modern electronics market, aesthetics play a significant role in consumer decision-making. ABS sheets are available in a wide range of colors, textures, and finishes, providing manufacturers with ample design flexibility. Whether it’s a sleek, glossy finish for a smartphone or a matte surface for a home appliance, ABS sheets can be easily customized to meet specific aesthetic preferences.

Additionally, ABS sheets can be painted, printed, or even molded with intricate patterns, giving manufacturers the ability to create unique and visually appealing products. This versatility in design helps electronics manufacturers differentiate their products in a competitive market, attracting consumers with stylish and attractive devices.

6. Sustainability and Recyclability

As sustainability becomes a growing concern in manufacturing, the demand for eco-friendly materials is increasing. ABS sheets are not only durable but also recyclable, which aligns with the global push for sustainable practices in the electronics industry. Recycled ABS can be reused to produce new components, reducing the need for virgin materials and minimizing waste.

Many ABS manufacturers in India and around the world are adopting sustainable practices in their production processes, ensuring that the material is environmentally friendly. As the electronics industry continues to evolve, the use of recyclable materials such as ABS sheets is expected to play a significant role in reducing the environmental footprint of electronic products.

7. Wide Availability of ABS Sheets

The availability of ABS sheets has also contributed to their widespread use in the electronics industry. India, for example, is home to numerous ABS manufacturers who produce high-quality sheets used in various industries, including electronics. For instance, 4×8 ABS sheet manufacturers in Gujarat and 4×8 sheet of ABS plastic exporters in Ahmedabad are key players in the global ABS sheet market, providing a steady supply of these essential materials.

Frequently Asked Questions about ABS Sheets

1. What makes ABS sheets ideal for electronics manufacturing?

ABS sheets are ideal for electronics manufacturing due to their durability, impact resistance, and excellent moldability. These properties allow them to protect electronic components from physical damage and environmental stressors while enabling manufacturers to create custom designs and functional parts.

2. Are ABS sheets environmentally friendly?

Yes, ABS sheets are recyclable, making them an eco-friendly option for electronics manufacturers. Recycling ABS sheets helps reduce the need for virgin materials and minimizes environmental waste, contributing to more sustainable production practices.

3. Where can I find reliable ABS sheet suppliers in India?

India is home to several reliable ABS sheet manufacturers and suppliers, including 4×8 ABS sheet manufacturers in Gujarat and ABS manufacturers in India. These suppliers offer high-quality sheets for various applications, including electronics, automotive, and industrial sectors.

Conclusion

ABS sheets offer numerous advantages to the electronics industry, including strength, durability, moldability, and cost-effectiveness. With their versatility in design, thermal and electrical insulation properties, and environmental sustainability, ABS sheets are helping shape the future of electronic products. As the demand for advanced electronics continues to grow, the role of ABS sheets will become even more crucial in ensuring the durability, performance, and aesthetic appeal of electronic devices.