Market Overview:

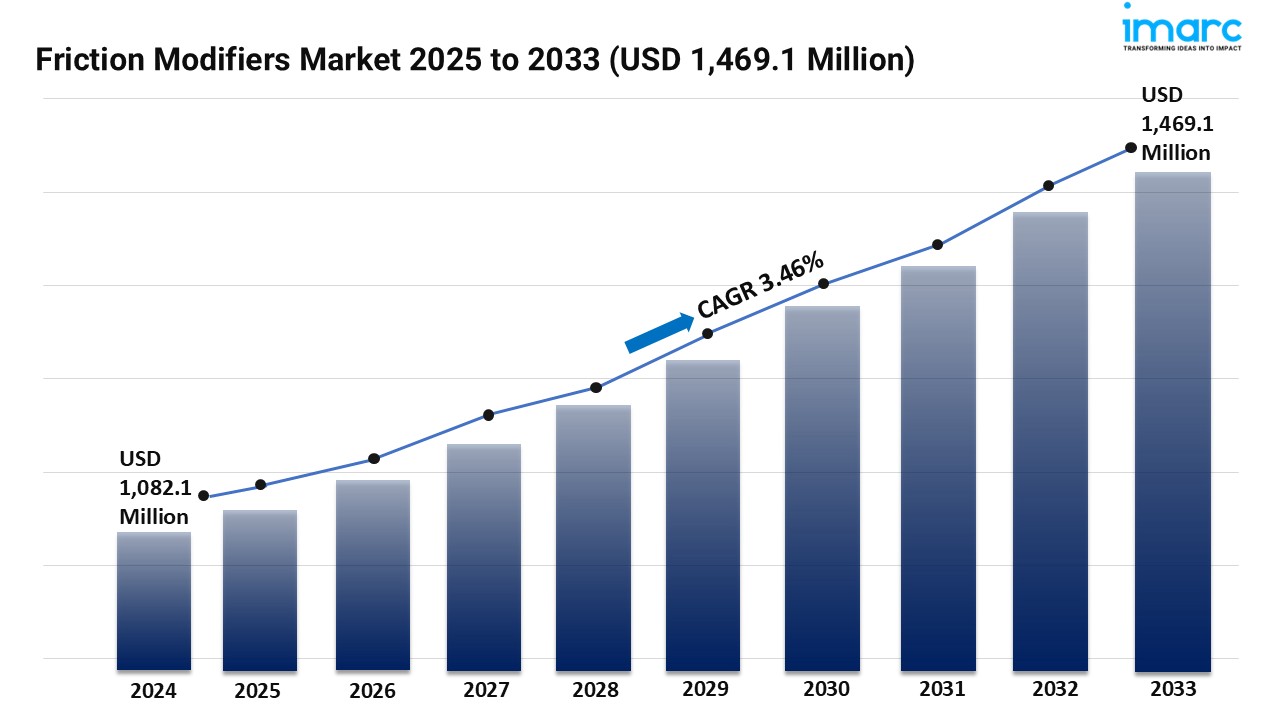

The friction modifiers market is experiencing rapid growth, driven by fuel efficiency & emission reduction, material science & nanotechnology and application diversification & customization. According to IMARC Group’s latest research publication, “Friction Modifiers Market Report by Type (Organic, Inorganic), End Use Industry (Automotive, Industrial, Marine, and Others), and Region 2025-2033“, offers a comprehensive analysis of the industry, which comprises insights on the global friction modifiers market share. The global market size reached USD 1,082.1 Million in 2024. Looking forward, IMARC Group expects the market to reach USD 1,469.1 Million by 2033, exhibiting a growth rate (CAGR) of 3.46% during 2025-2033.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and regional forecasts. The report offers a comprehensive overview and integrates research findings, market assessments, and data from different sources. It also includes pivotal market dynamics like drivers and challenges, while also highlighting growth opportunities, financial insights, technological improvements, emerging trends, and innovations. Besides this, the report provides regional market evaluation, along with a competitive landscape analysis.

Grab a sample PDF of this report: https://www.imarcgroup.com/friction-modifiers-market/requestsample

Our report includes:

- Market Dynamics

- Market Trends And Market Outlook

- Competitive Analysis

- Industry Segmentation

- Strategic Recommendations

Factors Affecting the Growth of the Friction Modifiers Industry:

- Fuel Efficiency & Emission Reduction:

The friction modifiers market experiences significant growth driven by the global imperative to increase fuel efficiency and reduce emissions. These dynamic strict regulatory mandates are fuel, such as cafe standards and euro -emission related, which forces to reduce the friction deficit in the engine and broadcast. In addition, the increasing consumers’ demand for fuel -competent vehicles and machines is running to use advanced friction modifies that improves lubricant performance. The focus on reducing greenhouse gas emissions and promoting sustainable transport is to intensify the demand for these additives. The development of the next generation friction modifies that provides better performance in low concentrations, increasing cost coffee and environmental benefits. Increasing electric and hybrid cars increases the development of special friction changes for electric powertrains and stores. The emphasis on increasing the gap for lubricant drains and reducing maintenance costs also contributes to the development of the market. The integration of nanotechnology and advanced material science enables the formation of friction modifications with sequential properties and extended durability. The increasing demand for lubricants for high declining in demand for applications, such as heavy vehicles and industrial names, operates innovation in wear and tear technology. This efficiency is not just about improving fuel economy; It is about contributing to a permanent future by reducing energy consumption and environmental impact.

- Material Science & Nanotechnology:

The friction modifiers market materials look at a strong tendency for science’s progress and nanotechnology integration, which is motivated by the need to achieve ultra-lo-friction and increase the safety of wear. It is filled with the development of dynamic novel materials, such as the graph, molibdenysulfide (MOS2) nanoping, and diamonds such as carbon (DLC) coating, which offers extraordinary tribal properties. In addition, the integration of nanotechnology enables the formation of friction modifications with particle size, surface imports and functionalities that optimize performance in specific applications. Focus on developing self -healing and adaptive friction modifies that can respond to changed operating conditions, increase the durability and life of greased components. The increasing demand for biocompatible and environmentally friendly durability is the development of bio -based and biodegradable materials. The emphasis on the spread of spread and stability of nanopartan in lubricants is important to ensure continuous performance and prevent aglomation. Advanced properties such as nuclear microscopy (AFM) and transmission electron microscopy (TEM) improves the deep understanding of friction -modifying behavior in nanoskale. The development of hybrid friction modify that combines different materials and functionalities expands the range of applications and performance properties. This material innovation is not just about using new materials; It is about engineering solutions at the molecular level to bring revolution in friction control and wear protection.

- Application Diversification & Customization:

The friction modifiers market is experiencing the increasing emphasis on the application variety and adaptation driven by the need to meet the specific requirements for different industries and operating environment. This dynamics are fueled from the growing demand for sewn friction modification, which can solve unique challenges with specific applications, such as metal fluids, unique challenges with fat and industrial lubricants. In addition, focusing on developing friction modifiers with specific functionalities, such as anti-WARE, anti-oxidation and corrosion bans, and expand the range of applications and performance properties. Under extreme operating conditions, increasing demand for modification of high down demonstration, such as high temperatures and high pressure, material choices and innovation design in innovation. The emphasis on offering custom friction modification solutions and technical support increases customers’ satisfaction and creates a long -term partnership. The development of friction change that can be integrated into advanced lubrication systems and smart machines increases operational efficiency and future maintenance skills. Increasing demand for friction change that can be used in additive production and 3D printing applications expands market capacity. Focusing on developing wear modifies used in lubricants in food quality and medical quality runs innovation in biocaptible and non-toxic materials. This diversification is not just about finding new uses; It is about creating special friction modification solutions that address specific requirements for different industries and applications, operates innovation and development in the market.

Leading Companies Operating in the Global Friction Modifiers Industry:

- ABITEC Corporation (ABF Ingredients Ltd.)

- ADEKA Corporation

- AFTON Chemical Corporation (NewMarket Corporation)

- Archoil

- BASF SE

- Chevron Corporation

- Croda International plc

- CSW Industrials Inc.

- Infineum International Limited

- King Industries Inc.

- Lanxess AG

- Vanderbilt Chemicals LLC (R.T. Vanderbilt Holding Company Inc.)

Report Segmentation:

The report has segmented the market into the following categories:

Breakup by Type:

- Organic

- Inorganic

Inorganic dominates the market due to its superior ability to withstand high temperatures and pressures, making it ideal for heavy-duty applications in automotive and industrial machinery.

Breakup by End Use Industry:

- Automotive

- Industrial

- Marine

- Others

Industrial holds the maximum number of shares as it requires high-performance lubricants to maintain machinery efficiency and reduce wear and tear, driving a consistent demand for friction modifiers.

Market Breakup by Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Asia Pacific’s dominance in the friction modifiers market is attributed to its robust automotive and industrial sectors, high vehicle production rates, and growing demand for fuel-efficient solutions in countries such as China and India.

Research Methodology:

The report employs a comprehensive research methodology, combining primary and secondary data sources to validate findings. It includes market assessments, surveys, expert opinions, and data triangulation techniques to ensure accuracy and reliability.

Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145