Global Honeycomb Sandwich Material Industry: Key Statistics and Insights in 2025-2033

Summary:

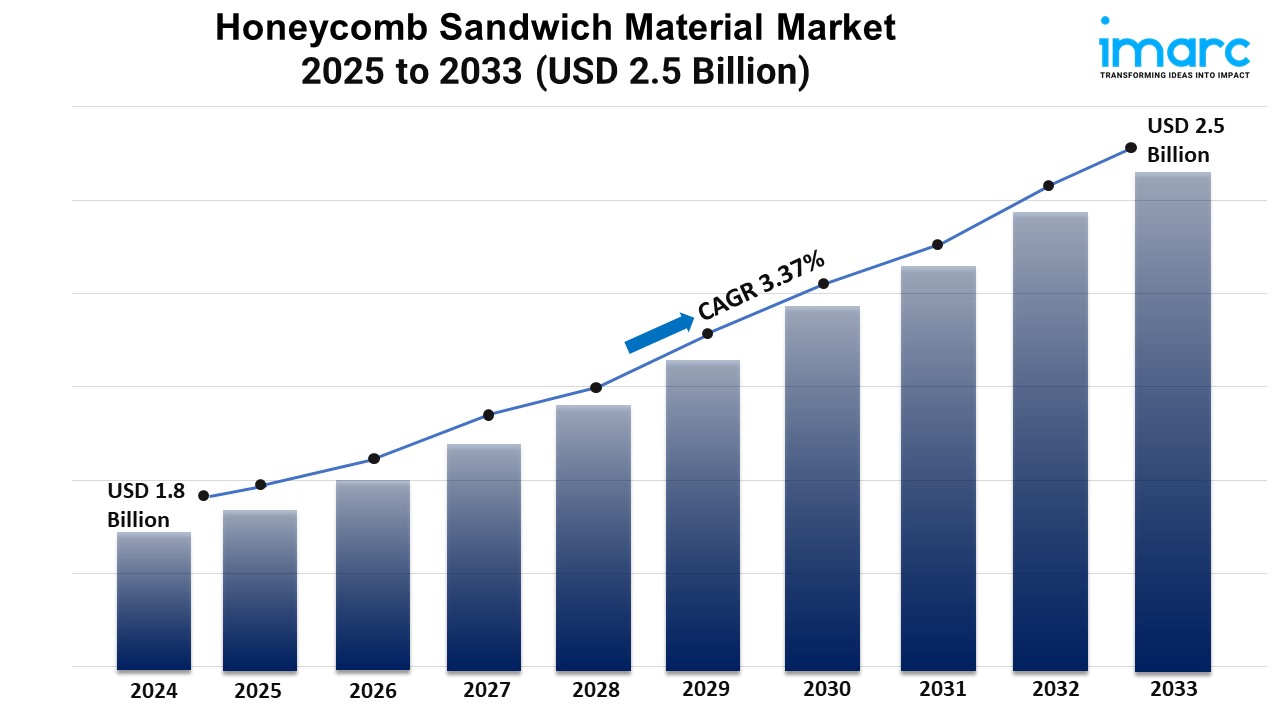

- The global honeycomb sandwich material market size reached USD 1.8 Billion in 2024.

- The market is expected to reach USD 2.5 Billion by 2033, exhibiting a growth rate (CAGR) of 3.37% during 2025-2033

- North America leads the market, accounting for the largest honeycomb sandwich material market share.

- Aluminum holds the majority of the market share in the material type segment due to its ability to offer resistance to corrosion and high temperatures.

- Expansion exhibits a clear dominance in the honeycomb sandwich material industry.

- Aerospace remains a dominant segment in the market, as it requires high-strength and durable components that can withstand extreme environmental conditions.

- The rising utilization in the construction sector is a primary driver of the honeycomb sandwich material market.

- Technological advancements in material production methods are reshaping the honeycomb sandwich material market.

Request for a sample copy of this report: https://www.imarcgroup.com/honeycomb-sandwich-material-market/requestsample

Industry Trends and Drivers:

- Thriving automotive industry:

The market for honeycomb sandwich materials is thriving due to the automotive industry’s obsession with the manufacture of lightweight vehicles, which would meet new strict emissions standards and fuel economy requirements. Indeed, light-weighted honeycomb structures are being used in body panels, chassis, and interior parts to improve the performance of vehicles. An increasing number of electric vehicles (EVs) is another driver for lightweights used to enhance battery range and energy utilization. This explains why the move would require the use of honeycomb materials, putting them at the forefront of automotive innovation and sustainability.

- Rising use in construction:

Being greatly valued because of their strength-to-weight ratio, honeycomb sandwich panels are more often employed in the construction industry, applied in facade construction, roofs and partitioning, while lowering structural load and simplifying construction processes. Evidently, honeycomb panels are providing improvements to thermal as well as acoustic insulation, hence energy efficiency and contrubition towards greener building designs; also offering an amazing versatility in shapes and finishes appealing for modern aesthetics in architecture, thus being able to provide that freedom of design. The durability and versatility are making honeycomb panels great importance for sustainable projects, which is bolstering the market growth worldwide.

- Technological advancements in material production:

New material technology innovations make possible the creation of products with better efficiency, longer durability, and a wider range of applications. Composite materials, such as carbon-fiber-reinforced and advanced polymer composites, have made possible improved properties of honeycomb structures including increased strength-to-weight ratio, increased impact resistance, and thermal stability. Further improvements in manufacturing processes including automated fabrication and 3D printing make it possible to produce solutions that meet specific performance criteria in more precise, less expensive ways, thus enabling more customization. New improved production methods will also enhance the speed and efficiency of scalability in honeycomb materials to become increasingly viable for applications and affordability.

We explore the factors driving the growth of the market, including technological advancements, consumer behaviors, and regulatory changes, along with emerging honeycomb sandwich material market trends.

Honeycomb Sandwich Material Market Report Segmentation:

Breakup By Material Type:

- Aluminum

- Steel

- Composites

- Titanium

- Inconel

- Others

Aluminum represents the largest segment due to its excellent strength-to-weight ratio and widespread use in aerospace and automotive applications.

Breakup By Technology:

- Expansion

- Corrugation

- Molding

- Extrusion

- Others

Expansion accounts for the majority of the market share as it allows for the efficient production of lightweight and high-strength honeycomb cores.

Breakup By Application:

- Aerospace

- Automotive

- Marine

- Locomotive

- Construction

- Others

Aerospace exhibits a clear dominance in the market because of the rising demand for lightweight materials in this industry to enhance fuel efficiency and structural integrity.

Breakup By Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

North America enjoys the leading position in the honeycomb sandwich material market owing to its established aerospace and defense industries and significant investments in advanced manufacturing technologies.

Top Honeycomb Sandwich Material Market Leaders:

The honeycomb sandwich material market research report outlines a detailed analysis of the competitive landscape, offering in-depth profiles of major companies. Some of the key players in the market are:

- 3M Company

- S. Innovation

- Corex Honeycomb (Encocam Ltd)

- EconCore N.V.

- General Veneer Manufacturing Co.

- Hexcel Corporation

- Honylite Private Limited

- Pacific Panels Inc.

- Samia Canada Inc.

- Schütz GmbH & Co. KGaA

- The Gill Corporation.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145