Store efficiency proves essential to warehouses and manufacturing plants and retail locations that manage products consisting of lengthy dimensions or substantial weight along with odd shapes. Cantilever racking represents the perfect solution for stalling materials that include timber along with pipes and steel and furniture as well as various other goods. authorization enables simpler movement of bulky cargo because this system features open-front design. Our guide will detail the advantages of the system together with its different types as well as how various sectors utilize it and essential safety measures and selection principles for boosting storage efficiency.

What is Cantilever Racking?

Cantilever racking represents a storage solution manufactured to accommodate large or bulky unstandardized items that standard pallet racks cannot manage efficiently.

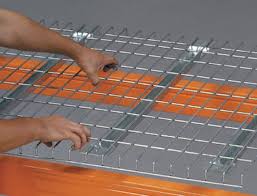

•The storage system includes important structural elements which form its basic design.

•The base component gives the structure its essential foundation which maintains stability.

•The uprights are vertical poles responsible for arm support in this storage structure.

•The storage components attached to the cantilever system extend in an outward direction to maintain the items on the arms.

• Bracing: Adds structural integrity and strength to the system.

• The absence of front columns in cantilever racks provides a superior access pathway for forklifts and manual handlers when operating within the storage space.

Benefits of Cantilever Racking

• Cantilever racking continues to be popular in storage solutions because it offers a broad list of useful characteristics.

• The open-front design makes it the best solution for storing lumber with its pipes and furniture and sheet metal.

• The open arrangement allows fast loading and unloading operation through forklifts when accessing the system.

• The system allows users to modify its structure by adjusting arms for customized storage applications.

• The system features a large heavy load capability because it was built to handle demanding materials.

• Warehouse storage becomes more effective because this system takes full advantage of vertical and horizontal areas.

Types of Cantilever Racking

Such storage solutions come in different cantilever racking designs to address specific storage requirements:

1. Light-Duty Cantilever Racking – Ideal for lightweight materials such as plastic pipes and smaller timber pieces.

2. Medium-Duty Cantilever Racking – Designed for moderate-weight items like plywood sheets and aluminum bars.

3. Heavy-Duty Cantilever Racking – Built for large and heavy materials such as steel beams and concrete panels.

4. Single-Sided vs. Double-Sided Racking:

Single-Sided Racking runs along walls because it conserves space.

• Double-Sided Racking – Provides access from both sides for higher storage capacity.

Industries That Use Cantilever Racking

Various industries choose cantilever racking because of its capability to fit different storage needs.

• Construction and Building Materials – Storage of lumber, steel pipes, drywall, and large beams.

Manufacturing facilities and metalworking facilities should use cantilever racking to store their steel sheets aluminum extrusions and metal rods.

• Furniture Storage – Used for sofas, mattresses, and wooden panels.

The automotive and aerospace sectors store their aircraft parts along with long vehicle components by utilizing this type of racking system.

Factors to Consider When Choosing Cantilever Racking

Implementation of cantilever racking requires businesses to evaluate the following points:

1. Determine the weight limit which your material storage system must withstand when selecting the system.

2. The available warehouse area requires measurement for picking between simultaneous two-sided rack use or sequential single-sided rack deployment.

3. The beneficial use of galvanized racks occurs outside due to their ability to withstand rust and prevent corrosion.

4. Select heavy-duty steel racks for heavy materials storage needs that extend into long periods of time.

5. Readiness to grow will depend on your selection of a scalable storage system.

Installation and Safety Guidelines

• Secure storage environments depend highly on correct installation and safety procedures for efficient performance.

• Manufacturers should provide installation instructions which must be followed correctly to achieve stability.

• Even distribution of loads across the arms will maintain balance by following Weight Distribution guidelines.

• Regular inspections need to be performed to check structural damage beyond verifying that both bolts and braces remain securely in place.

• An operator should not apply any loads beyond the safety specs defined in the weight capacity of the arms.

• The facility must follow warehouse safety rules so that workers remain accident-free and uninjured.

Cost Considerations and ROI

An initial capital expenditure for cantilever racking results in future advantages that include:

• Higher operational speed and faster product movement become achievable with this system.

• The appropriate storage methods protect products from becoming warped and bent.

• The optimal use of warehouse space allows businesses to reach maximum storage capacity.

Where to Buy Cantilever Racking in Melbourne

The search for top-quality cantilever racking solutions in Melbourne should start by considering these options:

• Local warehouse suppliers – Many offer installation and customization services.

• Industrial equipment distributors maintain different cantilever rack types which accommodate diverse operational needs.

• The process of purchasing online involves checking prices between suppliers and reading reviews before making the buy.

Conclusion

Cantilever racking provides necessary storage functionality to companies that need to organize long bulk materials. Applications for cantilever racking include warehouses as well as both construction sites and manufacturing facilities because of its accessible opening and strong weight-bearing capabilities and adjustable format. Businesses that use correct racking choices combined with proper safety protocols and installation measures gain improved storage productivity and protected goods together with optimized warehouse layouts.