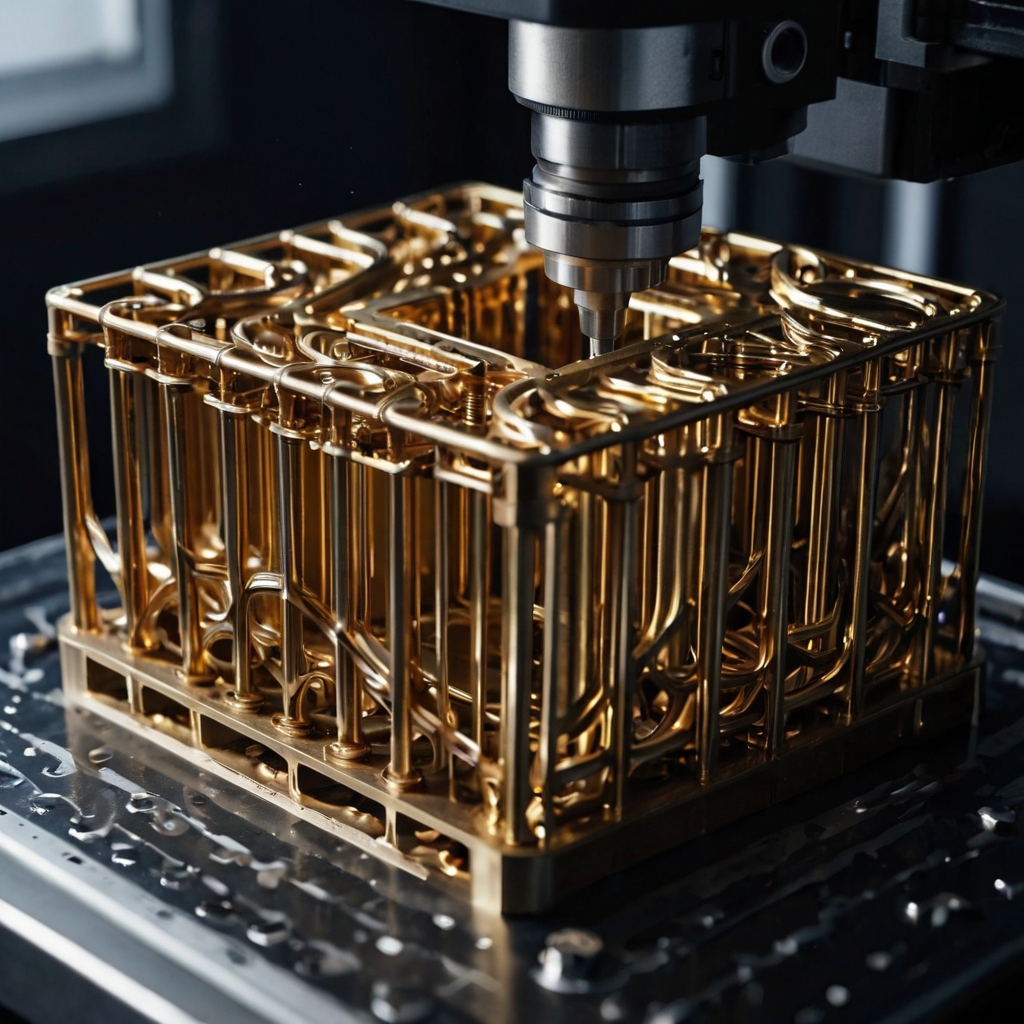

The manufacturing world has witnessed a remarkable transformation with the advent of 3D printing, also known as additive manufacturing. This technology has disrupted traditional production methods by enabling the creation of highly customized and complex parts with minimal material waste. Among the most exciting developments in the 3D printing landscape is the use of metals, which has opened up new possibilities for industries such as aerospace, automotive, healthcare, and defense. Metal 3D printing allows for the production of high-strength, lightweight components, and it is quickly gaining traction as a preferred method of manufacturing for specialized parts.

By 2031, the 3D Printing Metals Market is projected to experience robust growth, fueled by the demand for advanced manufacturing solutions in several key industries. One of the primary drivers behind this growth is the need for parts that are both strong and lightweight. In industries like aerospace and automotive, reducing the weight of components can result in significant improvements in fuel efficiency and overall performance. Metal 3D printing enables manufacturers to create highly durable, complex parts while also reducing material waste, making it an ideal solution for producing lightweight yet strong components. As industries continue to prioritize efficiency and sustainability, metal 3D printing is poised to play a critical role in future manufacturing.

The expansion of the 3D Printing Metals Market is also being driven by advancements in 3D printing technologies. The development of new metal alloys, improvements in printing speeds, and the introduction of more efficient post-processing techniques are making metal 3D printing more accessible and cost-effective. As a result, more industries are adopting this technology for the production of end-use parts, prototypes, and customized components. These advancements are expected to make metal 3D printing increasingly viable for businesses of all sizes, particularly as the technology becomes more affordable and easier to implement.

Aerospace is one of the most significant sectors benefitting from metal 3D printing, as the technology allows manufacturers to produce complex parts with reduced weight, which is crucial for improving fuel efficiency in aircraft. Similarly, the automotive sector is turning to metal 3D printing to produce lightweight components that can enhance vehicle performance and fuel economy. In addition to aerospace and automotive, healthcare is another sector seeing increased use of metal 3D printing. Custom implants and prosthetics made from metal are gaining popularity due to their ability to be tailored to an individual’s specific needs, improving patient outcomes.

While the future of the 3D Printing Metals Market looks promising, there are challenges to overcome. High material costs, specialized equipment, and the need for skilled operators remain significant barriers for some industries. However, as the technology matures and becomes more mainstream, it is expected that these obstacles will be mitigated. Increased investment in research and development will likely result in cost reductions, making metal 3D printing more accessible to a wider range of industries.

Looking ahead to 2031, the 3D Printing Metals Market is set to grow rapidly, driven by advancements in technology and the increasing demand for high-performance, lightweight, and customizable parts. As industries continue to seek ways to improve efficiency, reduce costs, and meet sustainability targets, the role of metal 3D printing will become even more crucial, making it an essential tool for the future of manufacturing.