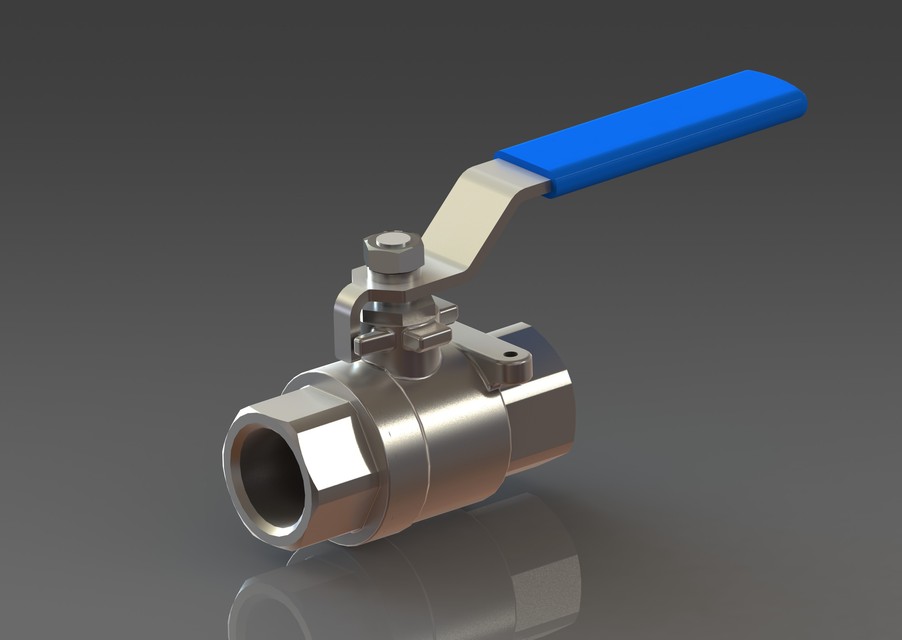

Stainless steel ball valves are a popular choice in various industries due to the inherent advantages of stainless steel itself. Let’s delve into why this material is so well-suited for these critical components.

1. Corrosion Resistance:

- The Big Win: Stainless steel, particularly austenitic grades like 304 and 316, is renowned for its exceptional resistance to corrosion. This is due to the formation of a protective chromium oxide layer on the surface, which acts as a barrier against corrosive agents.

- Why it Matters: This corrosion resistance is crucial in applications involving:

- Chemical Processing: Handling acids, alkalis, and other harsh chemicals.

- Pharmaceutical Industry: Maintaining product purity and sterility.

- Food and Beverage: Ensuring the integrity of food and beverage products.

- Marine Environments: Withstanding the corrosive effects of saltwater.

2. Strength and Durability:

- Built to Last: Stainless steel possesses high tensile strength and excellent durability, enabling it to withstand high pressures and temperatures. This translates to:

- Longer Lifespan: Valves made from stainless steel are less prone to wear and tear, reducing the need for frequent replacements.

- Reliable Operation: Even in demanding conditions, stainless steel valves maintain their structural integrity.

3. Temperature Resistance:

- Withstanding Extremes: Stainless steel exhibits excellent temperature resistance, performing well in both cryogenic and high-temperature environments. This versatility makes it suitable for a wide range of applications.

4. Hygiene and Sanitation:

- Cleanliness is Key: The smooth surface of stainless steel is easy to clean and sanitize. This is paramount in industries where hygiene is critical, such as:

- Food Processing: Preventing contamination of food products.

- Pharmaceutical Manufacturing: Maintaining sterile conditions.

5. Low Maintenance:

- Reduced Downtime: The inherent durability and corrosion resistance of stainless steel minimize the need for frequent maintenance and repairs. This translates to reduced downtime and lower operating costs.

6. Versatility:

- Adapting to Needs: Stainless steel ball valves are available in a wide array of configurations and sizes, making them adaptable to various applications and system requirements.

In Conclusion:

The combination of corrosion resistance, strength, temperature resistance, hygiene, and low maintenance makes stainless steel an ideal material for ball valves. By choosing stainless steel, industries can ensure the reliability, longevity, and safety of their fluid handling systems.