Selection of a proper mold-making company is critical,when you have set up your goals and objectives. In manufacturing industry or equipment for commercial retailers, the standards of molds define the effectiveness, longevity, and performance of the end products. Here in this blog you will know the qualities to look for in a mold making company that can help you get the best outcomes.

Expertise and Industry Experience

Mold-making from professionals gives you high quality of the final result. Seasoned organizations stand better chances of considering the various factors that may surround different industries and the various types of materials.

Professional engineers and designers, with years of practice in their field, work with your orders and offer the ideal molds. Also, their understanding of multiple manufacturing processes allows them to address the problems and provide the molds of the highest quality.

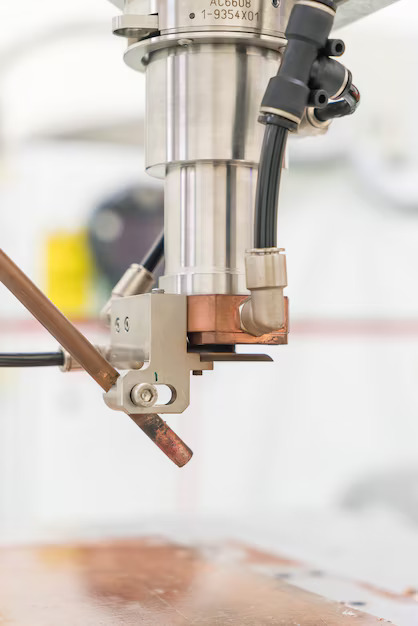

Advanced Technology and Equipment

Mold making is one of the processes in which technology plays an important role. Efficient organizations engage in procuring machinery such as the Computer Numerical Control, three-dimensional printers, and computer-aided design/computer-aided manufacture systems.

Modern technology enhances the ability to manufacture molds with great designs and small tolerances, hence minimizing mistakes and time wastage. While selecting a company, ask them about the tools and technologies used to work so you can check whether the tools meet the current industrial standards.

Material Quality and Selection

The materials used play a central role in determining the durability of molds, together with quality. A professional mold-making firm will produce products that you can use for the mold, such as aluminum, steel, or silicone, depending on the need of the project.

Selecting high-quality material for molds guarantees its repeated use and capability to work on various conditions at the same time. Ensure that the company has material management as a key priority and that information about the acquisition of high-quality materials is honored.

Customization and Design Capabilities

It is always important to solve each project and make respective changes to obtain the planned results. The most important mold-making companies currently offer consultative services to clients to ensure they are able to capture their peculiar requirements.

When designing a product from the ground up, the company should let you weigh in on all aspects of the final product—from ideas sessions to the first physical models. This cooperation will help to achieve the expected perfect match of the final mold and to fulfill all the functional demands.

Quality Control and Testing

Whereas quality assurance is always an important aspect, if not the most important aspect, of mold making. Molds are manufactured to specific standards, and it is always discouraged for such companies to compromise on quality due to the dangers it would send to their clientele.

Those companies go through several testing procedures, for example, durability tests and dimensional accuracy tests, before they release the final product. Attention to quality means a low defect rate and sustainable functional characteristics.

Reputation and Customer Support

The reliability of a mold-making company can largely be said to be based on the reputation tagged to it. It is necessary to look for reviews, testimonials, and case studies to assess successful work done by the company. Reputation management shows that getting a good reputation will ensure that one provides quality services consistently.

On the same note, reliable customer support is another sign of a reliable company as well. Beginning with occasional calls before ordering to calls to be made after delivering a product, the company that will respond to communication and customer satisfaction is better to deal with.

Conclusion

It is therefore important to carefully select the right mold making company to do the job in order to increase the chances of yields. Mere experience, technology, type of material used, extent to which they can personalize their products, quality assurance of their products, and their prestige are other areas that can be used to make the right decision. Working with a reputable firm is important, especially in ensuring high accuracy and durability of the products to foster product success. These aspects should be given topmost importance, and then look for a mold-making firm whom you wish to see as the partner for getting the best of results. Know more at Nub Plastic Inc.