Introduction

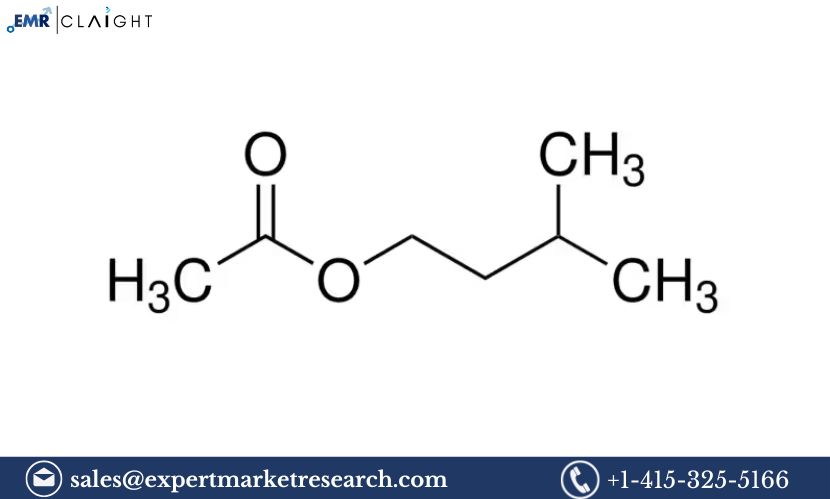

The Pentyl Acetate Manufacturing Plant Project Report provides a comprehensive guide to setting up a production facility for pentyl acetate, a widely used chemical compound in the fragrance, flavour, and chemical industries. Pentyl acetate, also known as amyl acetate, is an ester formed from the reaction between pentanol (amyl alcohol) and acetic acid. It is commonly used in perfumes, food flavourings, and as a solvent in various industrial applications. This report outlines the key components of establishing a pentyl acetate manufacturing plant, covering the market demand, manufacturing process, raw materials, plant design, and financial considerations.

Market Overview

Pentyl acetate finds significant applications in the food and beverage, cosmetic, and chemical industries. As an ester, it imparts a fruity or banana-like aroma, making it a popular ingredient in the fragrance and flavour industry. The global demand for natural and synthetic esters, especially in fragrances, flavourings, and solvents, has been growing steadily due to the increasing demand for consumer goods, particularly in food and personal care sectors.

Key Market Drivers:

- Food and Beverage Industry: Pentyl acetate is used as a flavouring agent in various beverages, snacks, and confections, especially those requiring a fruity or tropical flavour profile.

- Cosmetics and Personal Care: As a fragrance component, pentyl acetate is widely used in perfumes, deodorants, shampoos, and other cosmetic products.

- Solvent Industry: Pentyl acetate is used as a solvent in some chemical and pharmaceutical processes, driving demand in those sectors.

- Increasing Demand for Fragrances: With rising consumer spending on personal care and cosmetic products, the demand for fragrances, including those containing pentyl acetate, is growing.

Get a Free Sample Report with Table of Contents@

Key Market Segments:

- Fragrance Industry: The use of pentyl acetate in perfumes, air fresheners, and personal care products.

- Flavour Industry: Utilisation of pentyl acetate as a flavouring agent in foods and beverages.

- Solvent Market: As a solvent for certain chemicals and pharmaceutical products.

Raw Materials and Sourcing

The primary raw materials required for manufacturing pentyl acetate are pentanol (amyl alcohol) and acetic acid. These raw materials are available in the global market and can be sourced from chemical suppliers. Below are the key raw materials involved in the production of pentyl acetate:

- Pentanol (Amyl Alcohol): A primary alcohol with a fruity odour, which is the key reactant in the esterification process. Pentanol is derived from petroleum or can be sourced from bio-based materials.

- Acetic Acid: A colourless liquid with a strong, pungent smell, commonly available in the chemical market. Acetic acid is used to react with pentanol to produce pentyl acetate.

- Catalysts (Optional): In some cases, a catalyst such as sulfuric acid or an acid resin may be used to accelerate the esterification process.

The availability and quality of raw materials play a crucial role in ensuring the efficiency and consistency of production. Businesses should establish reliable relationships with suppliers to ensure consistent quality and timely deliveries of raw materials.

Manufacturing Process

The manufacturing process of pentyl acetate involves an esterification reaction between pentanol and acetic acid, typically catalysed by sulfuric acid. The steps involved in the process are:

1. Esterification Reaction:

- The primary reaction involves mixing pentanol and acetic acid in a reaction vessel. In the presence of an acid catalyst (such as sulfuric acid), the reaction produces pentyl acetate and water.

- The reaction is typically carried out under controlled temperature and pressure to maximize yield and prevent side reactions.

2. Separation of Water:

- Since water is a byproduct of the esterification reaction, it is removed from the reaction mixture. This is often done using a dehydrator or distillation column.

- The removal of water shifts the equilibrium toward ester production, improving the yield of pentyl acetate.

3. Purification and Distillation:

- After the reaction, the product mixture will contain pentyl acetate along with other by-products such as unreacted acetic acid and pentanol. To separate the desired pentyl acetate from these impurities, distillation is used.

- The mixture is heated in a distillation column, and pentyl acetate is separated based on its boiling point.

4. Drying and Final Purification:

- The distilled pentyl acetate may still contain traces of moisture, which must be removed using a drying agent or through further distillation.

- The final product is then subjected to quality checks to ensure that it meets industry specifications for purity, odour, and other properties.

Plant Design and Layout

Designing the pentyl acetate manufacturing plant involves planning for both efficiency and safety, ensuring compliance with local regulations, and accommodating the various stages of production. Below are the key considerations:

1. Raw Material Storage:

- A well-ventilated storage area is required for the storage of pentanol, acetic acid, and other chemicals involved in production. Proper safety measures should be in place, including spill containment systems and fire protection equipment.

2. Reaction and Distillation Area:

- The reaction vessel or reactor should be designed for controlled temperature and pressure. The distillation unit needs to be equipped with temperature controllers and safety mechanisms to ensure the safe separation of pentyl acetate.

3. Purification and Drying:

- A purification unit is needed for the final separation of pentyl acetate from any residual impurities. Drying equipment is also necessary to remove moisture from the final product.

4. Packaging and Storage:

- After the final purification, pentyl acetate is packaged into drums, bottles, or other suitable containers, depending on the intended market. A packaging area should be well-organized and equipped with automated systems for efficiency.

5. Safety and Waste Management:

- Proper safety measures should be in place to handle volatile chemicals like acetic acid and pentanol. The plant should include safety equipment such as fire extinguishers, emergency showers, and first-aid kits.

- Waste management systems must be in place to safely dispose of waste materials and by-products generated during production, such as spent solvents and water.

Financial Planning

Starting a pentyl acetate manufacturing plant requires a significant capital investment. The key financial components to consider are:

1. Initial Capital Investment:

- The investment includes the cost of purchasing land, building the manufacturing facility, and acquiring the necessary equipment such as reactors, distillation columns, drying units, and packaging systems.

- The capital investment will also cover the costs of raw materials, labour, and regulatory compliance.

2. Operating Costs:

- The operational costs include raw material procurement (pentanol and acetic acid), utilities such as electricity and water, labour, and maintenance of machinery.

- Other recurring expenses include transportation, insurance, and packaging costs.

3. Revenue Streams:

- Revenue will be generated from the sale of pentyl acetate to companies in the fragrance, flavour, and chemical industries.

- Potential for further revenue growth exists in custom formulations or supplying pentyl acetate to international markets.

4. Profitability:

- Profit margins depend on factors such as raw material costs, production efficiency, and market demand. Efficient production processes and economies of scale can help improve profitability.

Regulatory Compliance

Adhering to local and international regulations is vital to ensure the safety and legality of the pentyl acetate manufacturing plant. Key regulations include:

- Chemical Safety Standards: Compliance with regulations governing the safe use and storage of chemicals, such as OSHA (Occupational Safety and Health Administration) guidelines in the United States or REACH in Europe.

- Environmental Regulations: Ensuring that production does not harm the environment through improper disposal of waste or emissions. Proper handling of volatile solvents and by-products is critical.

- Health and Safety Standards: Ensuring worker safety during the manufacturing process by providing appropriate training, protective equipment, and emergency response procedures.

Marketing and Distribution Strategy

- Target Market: The primary markets for pentyl acetate include fragrance manufacturers, food and beverage producers, and chemical companies. This compound is especially sought after by companies looking to produce fruity-flavoured beverages and fragrances with tropical or banana-like notes.

- Distribution Channels: Pentyl acetate can be sold directly to manufacturers or through third-party distributors. Establishing a strong relationship with suppliers in the fragrance and flavour industry can significantly enhance market penetration.

- Brand Positioning: Position pentyl acetate as a high-quality, cost-effective solution for flavour and fragrance companies. Highlight its purity, versatility, and low environmental impact.

FAQ

1. What is pentyl acetate used for? Pentyl acetate is primarily used as a fragrance and flavouring agent in various consumer goods such as perfumes, food, and beverages.

2. What is the key chemical reaction in pentyl acetate production? The production of pentyl acetate involves an esterification reaction between pentanol and acetic acid, with sulfuric acid acting as a catalyst.

3. What industries use pentyl acetate? Pentyl acetate is used in the fragrance, flavour, and chemical industries, particularly for food and beverage flavourings, perfumes, and as a solvent.

4. What are the raw materials needed for pentyl acetate production? The primary raw materials for pentyl acetate production are pentanol (amyl alcohol) and acetic acid, along with optional catalysts like sulfuric acid.

5. Can pentyl acetate be produced sustainably? Yes, pentyl acetate can be produced sustainably by using renewable raw materials and employing eco-friendly manufacturing processes.

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au