The price of steel pipe plays a crucial role in many industries, from construction and plumbing to energy and manufacturing. Steel pipes are used in various applications, including transporting water, oil, gas, and other fluids, as well as in structural supports for buildings, bridges, and infrastructure projects. Because steel pipes are an essential component in these industries, understanding how their price is determined is key for buyers, whether you are a contractor, engineer, or individual looking to purchase steel pipes.

In this article, we will explore the factors that influence the price of steel pipe, different types of steel pipes, how to calculate their costs, and how global trends and local supply chains can impact the final price. Additionally, we’ll discuss strategies for obtaining the best deals on steel pipes for your projects.

Key Factors Affecting the Price of Steel Pipe

The price of steel pipe is determined by several factors, ranging from raw material costs to manufacturing processes, supply and demand, and even transportation expenses. Understanding these elements can help you make more informed purchasing decisions and anticipate changes in the market.

- Raw Material Costs

The cost of raw materials is one of the biggest factors affecting the price of steel pipe. Steel is made from iron ore, coal, and other materials, and any fluctuation in the prices of these commodities will have a direct impact on the final price of steel pipes. For example, when the price of iron ore increases globally, steel production costs go up, leading to higher steel pipe prices.

- Manufacturing Process and Pipe Type

The manufacturing process used to create the steel pipe is another crucial element in determining the price. Steel pipes can be made in various ways, and the complexity of the process plays a significant role in their cost.

- Global Supply and Demand

The price of steel pipe is also heavily influenced by global supply and demand dynamics. When there is a surge in demand for steel, particularly from construction projects or the oil and gas industries, the price of steel pipes can rise. Similarly, when global steel production is limited—due to factors like trade restrictions, labor shortages, or raw material shortages—the price of steel pipes can increase due to reduced supply.

- Transportation and Shipping Costs

Transportation costs are another major factor in the overall price of steel pipe. Steel pipes are heavy, bulky products that require significant resources to transport. The cost of shipping steel pipes depends on several factors, such as distance, fuel prices, and logistical infrastructure.

- Government Regulations and Tariffs

Government policies, regulations, and tariffs can have a significant impact on the price of steel pipe. In many countries, steel production is subject to government regulations, such as environmental standards and labor laws, which can increase production costs. Furthermore, some governments impose tariffs on imported steel in an effort to protect local manufacturers, which can raise the price of steel pipes sourced from abroad.

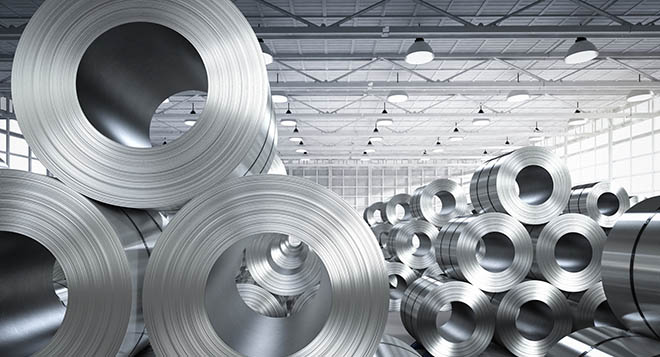

Types of Steel Pipes and Their Pricing

Steel pipes are available in a variety of grades, sizes, and finishes. The price of steel pipe can vary depending on the type of pipe you need and the specific requirements of your project.

Welded Steel Pipes: As mentioned earlier, welded steel pipes are typically the most affordable option. These pipes are suitable for general applications like plumbing, water transport, and HVAC systems.

Seamless Steel Pipes: These pipes are stronger and more durable than welded pipes, making them ideal for high-pressure environments such as oil and gas pipelines or industrial applications. Due to the complexity of their manufacturing process, seamless pipes are more expensive than welded pipes.

Galvanized Steel Pipes: Galvanized steel pipes are coated with a layer of zinc to prevent rust and corrosion. These pipes are commonly used in outdoor or marine applications and tend to be more expensive than regular steel pipes due to the galvanization process.

Stainless Steel Pipes: Stainless steel pipes are highly resistant to corrosion and are ideal for use in industries where hygiene is important, such as food processing and pharmaceuticals. These pipes are among the most expensive options due to the higher cost of the materials and the intricate manufacturing process.

Conclusion

The price of steel pipe is influenced by a variety of factors, including raw material costs, manufacturing processes, supply and demand, transportation expenses, and government policies. By understanding how these elements interact, buyers can make more informed decisions when purchasing steel pipes for their projects.

If you are looking for best quality tmt bars, please visit our website : www.steeloncall.com or you can contact us through our toll-free number: 18008332929

#priceofsteelpipe #steelpipes #steelpipesprice #priceofsteelpipestoday