Maintaining high quality in your CNC machine shop is crucial for customer satisfaction, repeat business, and staying competitive in the manufacturing industry. Whether you’re just starting out or looking to improve an established shop, focusing on quality can set you apart from the competition. In this blog, we’ll explore several effective strategies to help you maximize quality in your CNC machine shop.

Implement Effective Quality Control Processes

Quality control is the backbone of any successful CNC machine shop. Implementing robust quality control processes ensures that every product meets the required standards before it reaches your customers.

Establish Clear Standards

Start by defining what quality means for your shop. This includes setting specific standards for dimensions, tolerances, surface finishes, and material properties. Clear standards help your team understand the expectations and maintain consistency across all projects.

Note – Discover the difference a top-tier CNC machine shop can make for your projects. Raysun Techno Industries LLC offers exceptional precision, reliability, and expertise to meet all your manufacturing needs. Whether it’s custom fabrication or complex machining, trust Raysun Techno Industries LLC to deliver outstanding results every time.

Regular Inspections

Conduct regular inspections at various stages of the manufacturing process. This includes checking raw materials, during machining, and before final assembly. Early detection of issues can prevent costly mistakes and rework later on.

Use Quality Control Tools

Invest in quality control tools such as micrometers, calipers, and coordinate measuring machines (CMMs). These tools help accurately measure and verify the dimensions of your parts, ensuring they meet the required specifications.

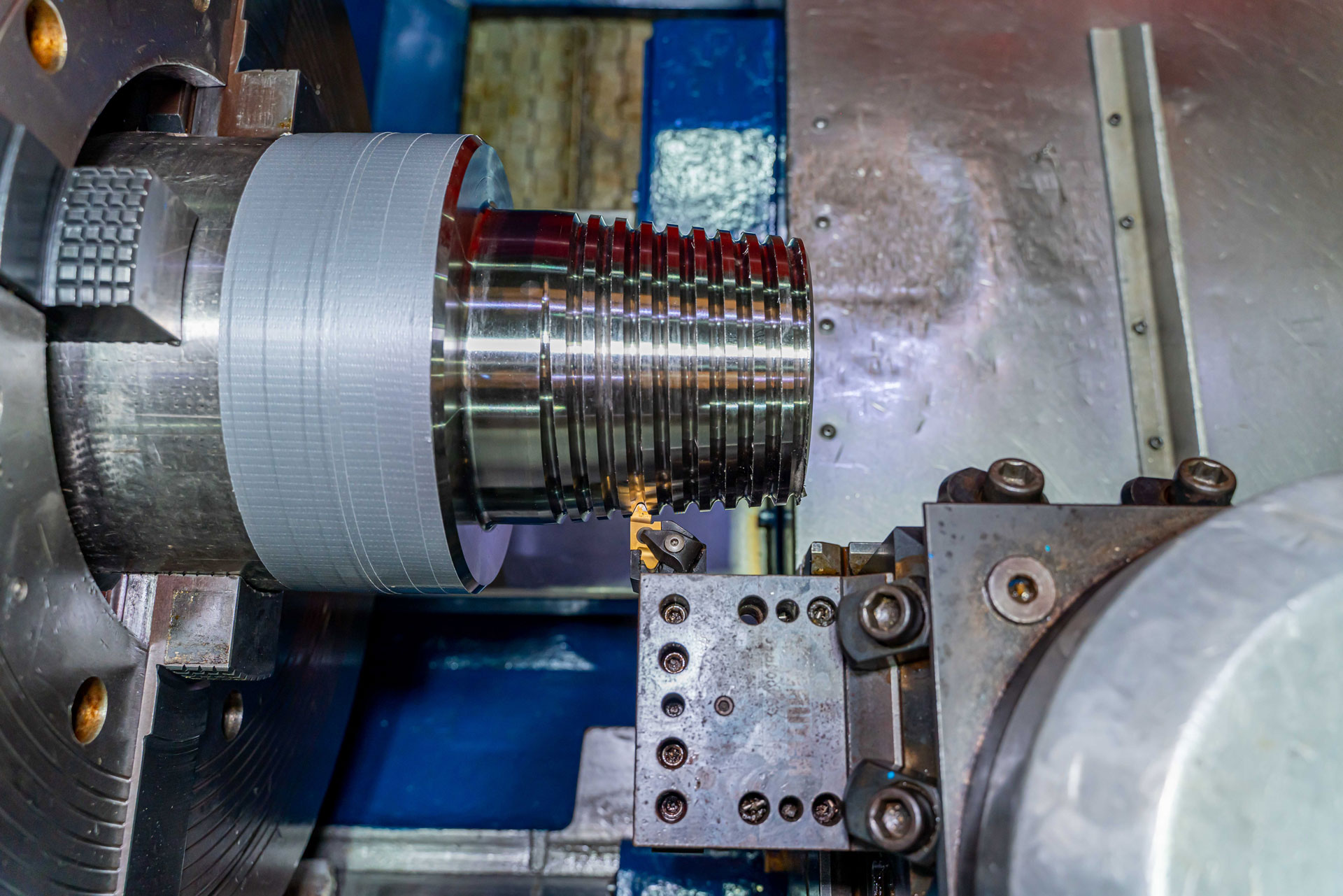

Invest in High-Quality Equipment

The equipment you use plays a significant role in the quality of your products. Investing in high-quality CNC machines and tools can lead to better precision and efficiency.

Choose Reliable CNC Machines

Select CNC machines from reputable manufacturers known for their precision and reliability. High-quality machines are less likely to break down and can produce more accurate parts consistently.

Upgrade When Necessary

Technology evolves rapidly, and keeping your equipment up-to-date can improve your shop’s capabilities. Upgrading to newer models with advanced features can enhance your production quality and efficiency.

Maintain Your Equipment

Regular maintenance is essential to keep your CNC machines running smoothly. Follow the manufacturer’s maintenance schedule and promptly address any issues to prevent downtime and maintain precision.

Train and Develop Your Workforce

Your team is a critical component of your CNC machine shop’s success. Investing in training and development ensures that your employees have the skills and knowledge to produce high-quality work.

Provide Comprehensive Training

Offer thorough training for new employees, covering machine operation, safety protocols, and quality standards. Ongoing training helps keep your team updated on the latest techniques and technologies.

Encourage Skill Development

Encourage your employees to develop their skills through workshops, courses, and certifications. Skilled workers are more likely to produce accurate and high-quality parts.

Foster a Quality-Oriented Culture

Promote a culture where quality is a top priority. Encourage your team to take pride in their work and understand the importance of maintaining high standards.

Regular Maintenance and Calibration

Keeping your machines in top condition is essential for maintaining quality. Regular maintenance and calibration help ensure that your CNC machines operate accurately and efficiently.

Schedule Routine Maintenance

Create a maintenance schedule that includes regular inspections, cleaning, and servicing of your CNC machines. Routine maintenance helps identify potential issues before they become major problems.

Calibrate Your Machines

Regular calibration ensures that your CNC machines produce parts with the correct dimensions and tolerances. Calibrate your machines according to the manufacturer’s guidelines or industry standards.

Keep Detailed Records

Maintain detailed records of all maintenance and calibration activities. This helps track the performance of your machines and identify patterns that may indicate the need for repairs or upgrades.

Streamline Communication and Workflow

Effective communication and streamlined workflows are essential for maintaining quality in your CNC machine shop. Clear communication helps prevent misunderstandings and ensures that everyone is working towards the same goals.

Use Clear Documentation

Provide clear and detailed documentation for each project, including specifications, drawings, and instructions. This helps your team understand the requirements and reduces the likelihood of errors.

Implement Efficient Workflow Processes

Design efficient workflow processes that minimize bottlenecks and ensure smooth transitions between different stages of production. An organized workflow helps maintain consistency and quality.

Foster Open Communication

Encourage open communication among your team members. Create an environment where employees feel comfortable sharing ideas, asking questions, and reporting issues. This can lead to improvements in processes and quality.

Continuous Improvement and Feedback

Continuous improvement is key to maintaining and enhancing quality in your CNC machine shop. Regularly seeking feedback and making necessary adjustments can lead to ongoing quality enhancements.

Collect Customer Feedback

Gather feedback from your customers about the quality of your products and services. Use this information to identify areas for improvement and address any issues promptly.

Conduct Internal Reviews

Regularly review your internal processes and performance. Identify areas where you can improve efficiency, reduce errors, and enhance quality.

Implement Lean Manufacturing Principles

Adopt lean manufacturing principles to eliminate waste and improve efficiency. Streamlining your processes can lead to higher quality and lower costs.

Choose the Right Materials

The quality of the materials you use directly impacts the quality of your final products. Selecting the right materials ensures that your parts meet the required specifications and perform as expected.

Source High-Quality Materials

Choose reputable suppliers that provide high-quality materials. Quality materials are less likely to have defects and can improve the overall quality of your products.

Verify Material Specifications

Ensure that the materials you receive meet the specified requirements. Verify material certifications and conduct inspections to confirm their quality.

Understand Material Properties

Have a good understanding of the properties of the materials you use. This knowledge helps you make informed decisions about machining processes and tooling, leading to better quality parts.

Monitor and Measure Performance

Tracking your performance is essential for maintaining quality. By monitoring key metrics, you can identify trends, measure progress, and make informed decisions to enhance quality.

Define Key Performance Indicators (KPIs)

Identify the key performance indicators that are relevant to your CNC machine shop. Common KPIs include first-time pass rate, production efficiency, and defect rates.

Use Data Analytics

Leverage data analytics tools to analyze your performance data. This can help you identify patterns, uncover root causes of issues, and make data-driven decisions to improve quality.

Regularly Review Performance

Schedule regular reviews of your performance metrics. Use these reviews to assess how well your quality initiatives are working and identify areas for further improvement.

Conclusion

Maximizing quality in your CNC machine shop requires a comprehensive approach that includes effective quality control, investing in the right equipment, training your workforce, maintaining your machines, streamlining communication, embracing continuous improvement, choosing the right materials, and monitoring your performance. By focusing on these strategies, you can ensure that your CNC machine shop consistently produces high-quality parts that meet your customers’ needs and set your business apart in the competitive manufacturing landscape.

Remember, quality is not a one-time effort but an ongoing commitment. Continuously seek ways to improve and adapt to new technologies and industry standards. By prioritizing quality, you’ll build a reputation for excellence that can lead to long-term success and growth for your CNC machine shop.

For more insightful articles related to this topic, feel free to visit bioneerslive.org