I-beams, named for his or her function “I” shape, are a cornerstone of cutting-edge construction. These robust structural additives are important in creating safe, durable, and efficient building frameworks. When searching for I-beams for sale, you’re making an investment in materials that make sure stability and reliability across numerous tasks.

As a key category of Steel Beams, I-beams are engineered to endure heavy hundreds, making them vital in construction, manufacturing, and infrastructure initiatives. Their specific design and functionality set them aside as one of the most depended on materials in structural programs.

What Are I-Beams?

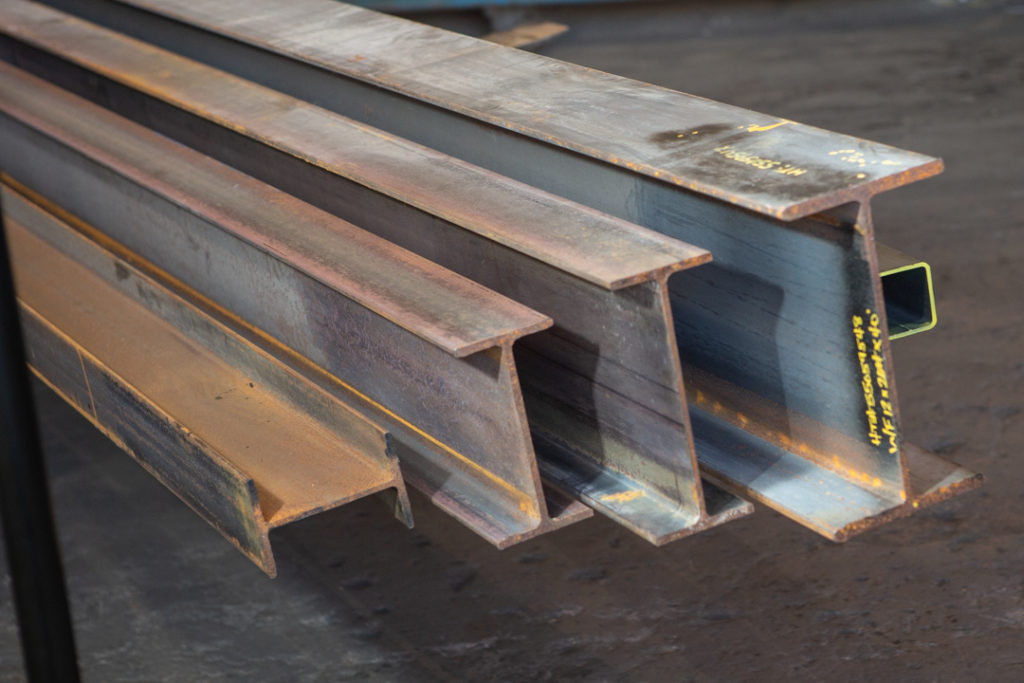

I-beams are metal beams with a awesome “I” or “H” cross-segment. This shape presents awesome electricity while minimizing cloth utilization, making them both cost-powerful and efficient. The vertical section, known as the internet, resists shear forces, while the horizontal flanges manage bending moments.

Available in a variety of sizes and materials, I-beams cater to diverse production desires, from residential frameworks to large-scale business structures.

Advantages of Using I-Beams

High Strength-to-Weight Ratio

I-beams provide advanced load-bearing ability without adding needless weight. This belongings ensures that structures stay solid and durable whilst reducing material prices.

Versatility

From bridges to excessive-rise homes, I-beams are utilized in numerous programs. Their ability to support both vertical and horizontal hundreds makes them best for growing sturdy and bendy frameworks.

Durability

Made from notable steel, I-beams are built to closing. Their resistance to put on, corrosion, and environmental elements guarantees they keep structural integrity through the years.

Applications of I-Beams

Construction

In construction, I-beams are generally used for structural help in homes, bridges, and warehouses. They form the skeleton of many skyscrapers, offering the strength required for tall structures.

Industrial Manufacturing

In industrial settings, I-beams are used to create systems, cranes, and heavy equipment frameworks. Their capacity to handle great masses makes them essential in manufacturing and assembly strains.

Infrastructure Development

Infrastructure projects, together with highways and railways, rely on I-beams for bridges and overpasses. Their strength and durability make sure secure and green transportation systems.

What to Consider When Looking for I-Beams for Sale

Material

Steel is the maximum not unusual cloth for I-beams due to its strength and sturdiness. However, different substances like aluminum or composite materials may be suitable for precise applications requiring lighter weight or corrosion resistance.

Size and Dimensions

The size of the I-beam must suit the weight necessities of your mission. Consulting with structural engineers can help you decide the precise dimensions for finest performance.

Compatibility with Other Steel Beams

In many tasks, I-beams are used along other Steel Beams to create a complete structural framework. Ensuring compatibility is crucial for keeping balance and strength.

Innovations in I-Beam Technology

The production industry is continuously evolving, and I-beams are not any exception. Advances in manufacturing techniques, including laser slicing and automatic welding, are making I-beams greater unique and efficient. Additionally, sustainable manufacturing methods are reducing the environmental impact of metal manufacturing.

Lightweight steel alloys and hybrid designs also are rising, offering improved electricity and versatility. These improvements make sure that I-beams stay a applicable and critical component in contemporary production.

The Role of I-Beams in Sustainable Construction

Sustainability is a developing focus in the construction industry, and I-beams play a crucial position on this shift. Steel is a recyclable material, which means that I-beams may be reused or repurposed on the give up of a structure’s existence. This reduces waste and contributes to a round economy.

Moreover, the performance of I-beams in load-bearing applications minimizes the amount of fabric required, in addition supporting eco-friendly constructing practices.

Tips for Choosing the Right I-Beams

- Assess Load Requirements: Determine the forms of masses your shape will face, along with static and dynamic forces.

- Consider Environmental Factors: If the structure can be exposed to harsh climate or corrosive environments, choose covered or galvanized steel I-beams.

- Source from Reliable Suppliers: High-best I-beams on the market make certain long-lasting performance and protection.

Why I-Beams Are a Long-Term Investment

Investing in I-beams is not just about shopping a product; it’s approximately securing the future of your project. The power and durability of I-beams reduce the want for frequent maintenance or replacements, saving time and money in the end.

Their versatility way they may be adapted to numerous makes use of, ensuring that they remain applicable while venture demands evolve. Whether you’re constructing a skyscraper, a bridge, or an industrial facility, I-beams provide the foundation for achievement.

Conclusion: Building a Strong Future with I-Beams

The demand for I-beams for sale reflects their significance in shaping the arena round us. As a subset of steel beams, they offer unmatched electricity, versatility, and durability. From their precise layout to their position in sustainable construction, I-beams are crucial in meeting the demanding situations of modern-day infrastructure and industrial initiatives.

Whether you’re embarking on a new creation undertaking or upgrading current infrastructure, I-beams are a reliable choice for building a sturdy and sustainable destiny. Their tested track record in diverse packages ensures they stay a cornerstone of development in production and beyond.