In the world of packaging, organizations are continually seeking approaches to enhance overall performance, reduce operational prices, and decorate product presentations. One of the key alternatives in this regard is choosing the proper kind of applicator for sleeve labeling. Automatic shrink sleeve applicator and manual applicator each have their vicinity in packaging operations, however, which one is better for your business? This blog will discover the benefits, challenges, price, and usage of Automatic Shrink Sleeve Applicator with numerous enterprise needs.

Understanding Shrink Sleeve Applicator:

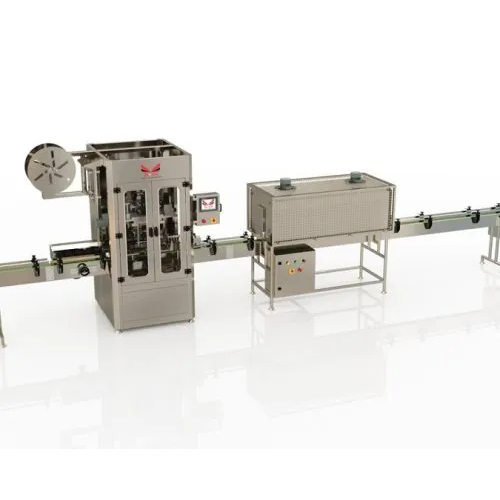

Before diving into the comparison, permit in short define what shrink sleeve applicator do. These machines are designed to use cut returned sleeves—plastic movies that reduce again round a product even as warmth is finished. The cease result is a first-rate, smooth, and expert-looking label, usually used for bottles, cans, and jars. Shrink sleeves are perfect for quite several industries, from food and beverage to cosmetics and prescribed drugs.

Automatic Shrink Sleeve Applicator VS Manual Shrink Sleeve Applicator

- Speed and Performance

- Automatic Shrink Sleeve Applicator:

Computerized machines are the clear winners when it comes to speed and efficiency. The automatic sleeve reduction system can track sleeves quickly and continuously. This greatly increases the throughput. with computer skills Including a computerized bottle capping machine. automatic labeling structure and automatic packing sealing Streamline the entire packaging process. - Manual Shrink Sleeve Applicator:

Alternatively, manual machines require an operator to remove the utility casing. This can be slow and vulnerable to human error. This approach is not very environmentally friendly. especially large-scale production operations This can cause inconsistencies and delays.

If your commercial organization requires high-speed, high-volume packaging. An automatic Shrink Sleeve Applicator will provide the speed and consistency needed to meet the demands.

2. Cost

- Automatic Shrink Sleeve Applicator:

The initial capital cost for automatic casing reduction spray nozzles is higher as compared to manual machines. However, the long-term blessings outweigh the accusations. By reducing labor requirements, reducing errors, and improving efficiency, businesses often reap substantial returns on their investments. Additionally, Automatic shrink sleeve applicator machines with automatic bottle capping Along with manufacturers, automatic labeling systems also offer versatility and reliability. - Manual Shrink Sleeve Applicator:

Manual users are much less expensive prematurely and may be more suitable for smaller operations or agencies just starting out. But it often leads to higher effort costs over time. and when the demand for production increases Scalability can become an issue.

For businesses aiming for boom and lengthy-time period profitability, the investment in automatic machines is worthwhile in phrases of productivity and value-effectiveness.

3. Precision and Consistency

- Automatic Shrink Sleeve Applicator:

Automatic machines are designed to ensure particular sleeve placement, reducing the probability of errors. With incorporated capabilities like photoelectric sensors, automatic cap sleeve applicator machines, and automatic sleeve bottle sticker labeling machines, those machines make sure that every product is classified because it ought to be and constantly, improve the awesome of the product’s presentation. - Manual Shrink Sleeve Applicator:

In guide structures, precision largely relies upon the potential and consistency of the operator. While operators can however gather satisfactory effects, there’s an extra risk for misalignment, wrinkles, or different imperfections within the sleeve.

For groups looking to optimize labor costs and reduce downtime, automatic shrink sleeve applicators are the higher desire.

4. Labor and Maintenance Requirements

- Automatic Shrink Sleeve Applicator:

Automatic machines require minimum human intervention once set up, allowing personnel to focus on different important obligations. While computerized filling gadget producers produce machines that require a little technical information, these machines are generally designed for smooth preservation and lengthy-lasting durability, minimizing downtime. - Manual Shrink Sleeve Applicator:

Manual machines require ongoing human involvement, main to a better exertion price. The need for operators and capacity for human mistakes also can result in overtime spent on changes or maintenance.

For businesses trying to optimize hard work prices and reduce downtime, Automatic cut-back sleeve applicators are the higher desire.

5. Versatility and Flexibility

- Automatic Shrink Sleeve Applicator:

Automatic machines, just like the automatic cut lower back sleeve tool manufacturer, are able to deal with various bottle configurations and dimensions, making them best for companies with numerous packaging desires. They can seamlessly combine with other structures consisting of automatic bottle capping machines or computerized cap sealing machines for a fully automatic packaging line. - Manual Shrink Sleeve Applicator:

Manual applicators are commonly applicable for smaller-scale operations with less complex packaging needs. While they may be able to cope with pretty a few products, common modifications, and guide labor can be required while converting sizes or codecs.

Automatic machines provide greater flexibility and scalability, making them perfect for companies in search of diversifying their product traces.

Price of Automatic Shrink Sleeve Applicator

The charge of automated cut lower back shrink sleeve applicators can vary primarily based on elements much like the machine’s functions, ability, and generation. On not unusual, groups can anticipate to make investments extra initially in an automatic device. However, with lower operational costs and a higher price of productivity, the machines fast pay for themselves.

Estimated Price Range

For a simple decrease sleeve applicator tool for bottles, expenses can start from ₹5,00,000 to ₹10,00,000 ($6,000 to $12,000 USD). High-quit, function-wealthy fashions like automatic decrease sleeve machines for bottles can pass past ₹15,00,000 ($18,000 USD) depending on the specifications.

Industry Applications and Benefits

- Food and Beverage

Automatic shrink sleeve applicators are broadly used within the food and beverage industry, making sure that merchandise is packaged hygienically and attractively. From cut-back shrink sleeve applicator machine for bottles to automatic cap sealing machine, these machines guide high-throughput strains simply. - Pharmaceuticals

For pharmaceuticals, regular and stable labeling is vital. Automatic structures offer tamper-evident shrink sleeves that beautify security. Partnering with a good automatic filling machine manufacturer can assist make certain an quit-to-cease, dependable packaging system. - Personal Care and Cosmetics

In the aggressive cosmetics marketplace, pleasing and perfectly aligned labels are essential for emblem photography. Automated machines like round bottle sticker labeling machines provide precision that appeals to pleasant-targeted customers.

Which Option is Best for Your Business?

Choosing between an automatic and manual shrink sleeve applicator comes right down to your manufacturing requirements, finances, and commercial enterprise dreams. If your organization prioritizes speed, consistency, and scalability, an automatic shrink sleeve applicator will probably be the fine healthy. Smaller agencies or those with restrained runs may additionally discover a manual system that meets their needs without the better advance fee.

In any case of your desire, running with a trusted automatic shrink sleeve applicator will ensure you get hold of the support and steerage needed to make the right funding. Boss Packaging offers fantastic, dependable shrink sleeve solutions and lets you decide on the first-rate applicator to your specific wishes.