In today’s technology-driven world, efficient thermal management is critical for ensuring the reliability and performance of electronic systems, spacecraft, and advanced energy systems. As components become more compact and powerful, managing the heat they generate has become increasingly complex. This is where thermal analysis comes into play. This article delves into thermal analysis, its significance in thermal management, and its applications across various industries.

What is Thermal Analysis?

Thermal analysis is the study of how materials and systems respond to changes in temperature and heat flow. It involves measuring the physical and chemical properties of materials as they undergo temperature changes. This process is crucial for understanding thermal behavior, which includes how heat is generated, transferred, and dissipated within a system. By conducting thermal analysis, engineers can predict potential overheating issues, optimize designs, and ensure the reliability of products across various applications.

Importance of Thermal Management

Thermal management refers to the techniques and methods used to control the temperature of a system or component to ensure optimal performance. Effective thermal management is vital in preventing overheating, which can lead to reduced efficiency, component failure, and even safety hazards. Industries increasingly rely on advanced thermal management solutions to maintain the reliability and longevity of their products.

Techniques in Thermal Analysis

Various techniques are employed in thermal analysis to assess heat transfer and management. Here are some of the most widely used methods:

1. Steady-State and Transient Heat Transfer Analysis

- Steady-State Analysis: This approach assumes that the temperature of a system remains constant over time. It is used to evaluate scenarios where heat generation and loss are in balance. For example, in electronics cooling, steady-state analysis helps determine the maximum allowable temperature for components under continuous operation.

- Transient Analysis: Unlike steady-state analysis, transient analysis considers the time-dependent behavior of a system. This technique is crucial for evaluating how a system responds to rapid changes in temperature or heat input. In applications like spacecraft electronics, transient analysis helps predict thermal behavior during launch and re-entry.

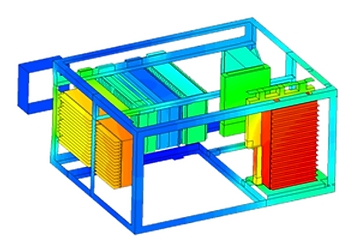

2. Computational Fluid Dynamics (CFD)

CFD plays a significant role in thermal analysis, particularly in systems where fluid flow impacts heat transfer. Coupled CFD/thermal simulations enable engineers to model complex interactions between fluid dynamics and thermal phenomena, providing insights into how airflow can enhance or hinder cooling in electronic devices.

3. STOP (Structural, Thermal, Optical) Analysis

STOP analysis integrates thermal, structural, and optical considerations to evaluate the performance of systems that rely on precise thermal management. This method is essential for applications such as optical components, where temperature variations can significantly affect performance. Engineers can predict thermal distortion, surface accuracy, and stress birefringence, ensuring optimal operation in challenging environments.

Applications of Thermal Analysis in Various Industries

Thermal analysis has a wide range of applications across different industries, showcasing its versatility and importance. Here are some key areas where thermal analysis and management play a crucial role:

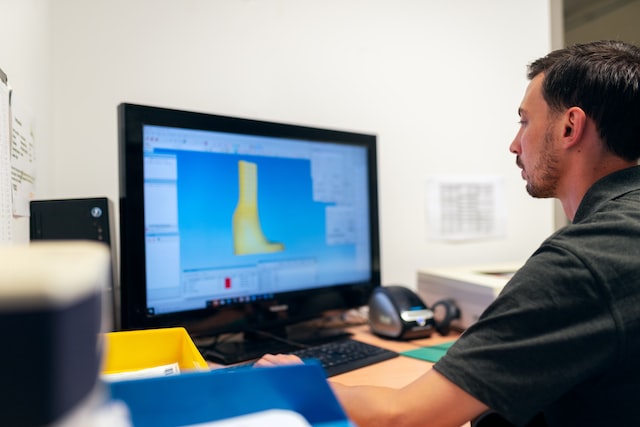

1. Electronics Cooling

In the electronics industry, effective thermal management is essential to prevent overheating and ensure reliable performance. Thermal analysis techniques, including steady-state and transient heat transfer evaluations, help design cooling solutions for consumer electronics, military systems, and ground-based telescopes.

2. Aerospace and Spacecraft

Thermal analysis is critical in the aerospace industry, where components must withstand extreme temperature variations during launch and orbit. Engineers utilize thermal management solutions to protect sensitive electronics in spacecraft, ensuring proper functioning in the harsh environment of space. Applications include on-orbit thermal modeling, cryogenic systems, and external aerodynamics.

3. Advanced Energy Systems

In the renewable energy sector, thermal analysis is employed to optimize the performance of advanced energy systems, such as solar panels and batteries. By understanding heat generation and transfer, engineers can improve energy efficiency and reliability, paving the way for sustainable technologies.

Software Tools for Thermal Analysis

To effectively perform thermal analysis, engineers rely on advanced software tools designed for various applications. Some of the leading software tools include:

- MAYA/ESC: Used for electronics cooling and coupled CFD/thermal simulations, allowing for detailed analysis of heat transfer mechanisms.

- Thermal Desktop (SINDA/FLUINT): A full-purpose code designed for spacecraft on-orbit thermal modeling and radiation analysis.

- STAR-CCM+: Ideal for addressing complex thermal and CFD problems, incorporating multi-physics and aero-heating simulations.

- Nastran, Abaqus, & ANSYS: These tools are widely used for thermal distortion and heat transfer problems, enabling engineers to conduct detailed analyses.

- Quartus STOP Toolkit: An internal Matlab tool specifically designed for optical performance analysis, integrating thermal management considerations for optical systems.

Conclusion

In conclusion, thermal analysis is a crucial discipline for effective thermal management across various industries. By understanding the principles of heat transfer and employing advanced techniques, engineers can optimise designs, prevent overheating, and enhance the reliability of products. As technology continues to evolve, the importance of thermal management solutions will only increase, making thermal analysis an indispensable tool in the engineering toolkit. Through continued innovation and expertise in thermal management, industries can ensure the performance and longevity of their systems, ultimately contributing to technological advancement and sustainability.