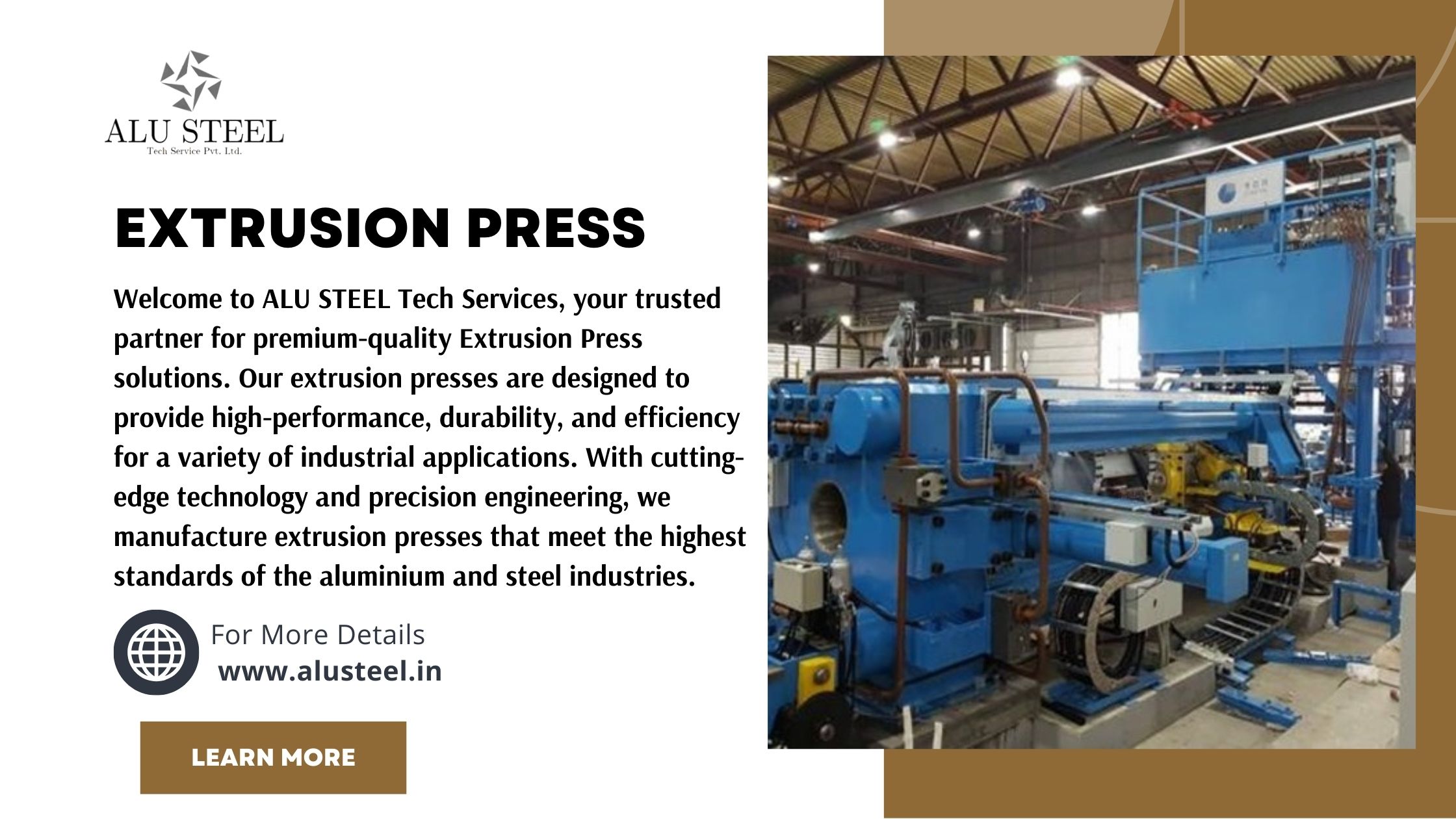

In today’s industrial world, extrusion technology is crucial for transforming materials like aluminum, steel, and other metals into precise, uniform shapes that are used in various industries. At ALU STEEL Tech Services, we offer advanced extrusion press solutions that are designed to meet the changing demands of manufacturers. Our extrusion presses are recognized for their durability, efficiency, and precision, making them a preferred choice for companies seeking to improve their production processes and capabilities.

What is an Extrusion Press?

An extrusion press is a powerful mechanical device used to shape raw metal materials into specific profiles by forcing the material through a die. The extrusion process results in long, continuous shapes, such as rods, tubes, and profiles, which are used across a wide range of industries, including construction, automotive, aerospace, and manufacturing.

One of the key benefits of extrusion technology is its ability to create complex cross-sectional designs with high precision and minimal waste, resulting in cost-effective and sustainable manufacturing practices. This process is particularly beneficial for industries that require high-quality, uniform parts.

Key Features of ALU STEEL Tech Services Extrusion Press

At ALU STEEL Tech Services, we design our extrusion presses to deliver outstanding performance across different industrial applications. Below are some of the key features that make our products stand out:

1. Precision Engineering

Our extrusion presses are built with precision engineering, ensuring that every extrusion meets the exact specifications and quality standards. Whether you’re working with aluminum or steel, our presses deliver consistent results, maintaining uniformity across all products.

2. Durability

We manufacture our presses from high-quality materials, ensuring their durability and longevity. Our machines are designed to withstand the rigors of heavy industrial use, reducing wear and tear, and minimizing the need for frequent maintenance and repairs.

3. Custom Solutions

Every industry has unique requirements, which is why we offer customizable extrusion presses. Our presses can be tailored to suit specific production line needs, whether you’re operating a small-scale or large-scale business. This flexibility makes our machines ideal for companies with unique or evolving production demands.

4. Energy Efficiency

Energy efficiency is a critical factor in modern manufacturing. Our extrusion presses are optimized for energy-efficient performance, allowing manufacturers to lower their energy consumption and operational costs while maintaining high productivity levels.

5. Ease of Maintenance

Our presses are designed with ease of maintenance in mind. Quick servicing features reduce downtime, allowing your production line to function smoothly and consistently. This ensures that your machine stays in top working condition, minimizing potential disruptions in your operations.

Applications of Extrusion Press Technology

Extrusion presses are used in numerous industries due to their versatility and efficiency. Here are some of the most common applications:

1. Aluminum Extrusions

Aluminum extrusions are widely used in the automotive, aerospace, and construction industries because they are lightweight, durable, and corrosion-resistant. Our extrusion presses can produce components such as window frames, car parts, and aircraft fuselage sections with remarkable precision and efficiency.

2. Steel Extrusions

Steel extrusion is essential for creating structural components for heavy industries like infrastructure, machinery, and rail systems. Our presses can produce strong, precise steel extrusions that are built to withstand harsh conditions and demanding environments.

3. Custom Extrusions

Many industries require custom extrusions to meet specific design needs. Our extrusion presses can be customized to produce complex shapes that are vital for specialized manufacturing applications. Whether you need intricate profiles or custom designs, our presses are up to the task.

Benefits of ALU STEEL Tech Services Extrusion Presses

Choosing an extrusion press from ALU STEEL Tech Services offers several benefits that can enhance your production processes and improve overall efficiency. Here’s why companies trust us:

1. Enhanced Productivity

Our extrusion presses are designed for high-speed, efficient operation, allowing businesses to increase their output without sacrificing quality. This makes them ideal for companies looking to scale their production without compromising precision or reliability.

2. Better Material Utilization

Extrusion technology is inherently waste-efficient, allowing for more efficient use of raw materials. This results in reduced waste and better material utilization during production, helping companies cut costs and improve sustainability.

3. Versatility

Whether you’re working with aluminum, steel, or other metals, our extrusion presses can handle a wide range of materials. This versatility enables manufacturers to produce simple as well as complex designs for various applications, making our presses a flexible choice for diverse production needs.

4. Cost Savings

The energy-efficient operation and durable construction of our presses lead to significant cost savings over time. Reduced energy consumption, minimal maintenance requirements, and long-lasting performance help businesses maximize their return on investment.

Why Choose ALU STEEL Tech Services?

At ALU STEEL Tech Services, we combine decades of industry expertise with a commitment to innovation. We strive to provide extrusion press solutions that meet and exceed our clients’ expectations. Here’s why we are the preferred choice for manufacturers:

1. Unmatched Expertise

With years of experience in the aluminum and steel industries, we understand the unique challenges of extrusion manufacturing. We have developed innovative solutions tailored to meet the specific needs of modern production environments.

2. Comprehensive Support

We offer end-to-end support, from the initial consultation to the installation and ongoing maintenance of your extrusion press. Our team is dedicated to ensuring that your press delivers optimal performance, helping you achieve your production goals with minimal disruption.

3. Tailored Solutions

We understand that every business has unique requirements. That’s why we work closely with our clients to provide customized extrusion press solutions that align with their specific production needs. This ensures that you get the right equipment to fit your operational goals.

For more details on our custom solutions, you can also explore our Custom Solutions for Extrusion Presses page.

Conclusion

An extrusion press is a vital piece of equipment for any manufacturing business that requires precise and uniform metal shaping. At ALU STEEL Tech Services, we provide high-quality extrusion press solutions that offer durability, efficiency, and customization options. Whether your business operates in the aluminum or steel industry, our presses can help you boost productivity, reduce waste, and improve overall efficiency.

Contact us today to learn more about how our extrusion press solutions can revolutionize your production line and help you achieve your industrial objectives.