In the realm of industrial applications, where performance and durability are paramount, choosing the right material for components such as flanges can make a significant difference. One material that stands out for its exceptional properties is Alloy 20. Known for its impressive corrosion resistance, Alloy 20 Flanges are an ideal choice for a variety of demanding environments, including chemical processing and marine applications. But what exactly makes Alloy 20 Flanges so special? Let’s dive into their unique properties, specifications, and benefits to understand why they are a preferred choice for industries worldwide.

What Are Alloy 20 Flanges?

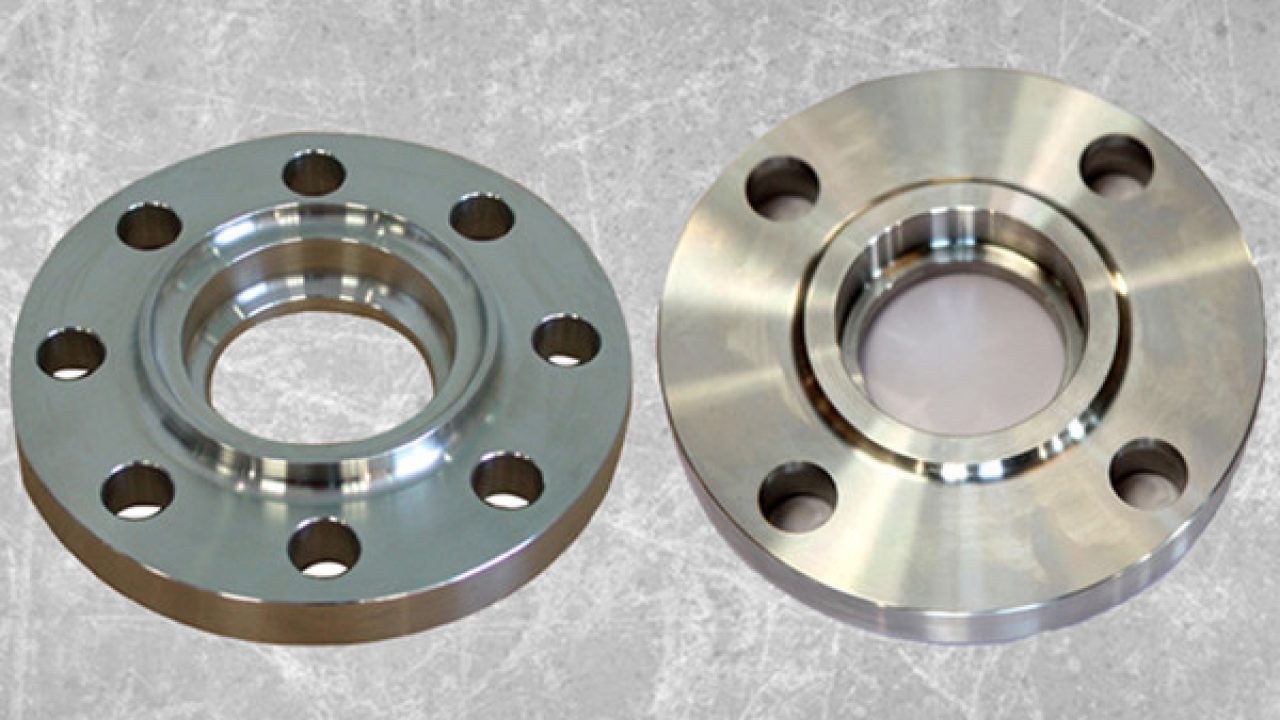

Alloy 20, also known as Carpenter 20, is a nickel-iron-chromium austenitic alloy with additions of copper and molybdenum. It is specifically designed to withstand extreme environments where high resistance to acidic substances is required. Alloy 20 Flanges, made from this versatile alloy, offer superior protection against stress corrosion cracking and pitting in a range of challenging industrial conditions.

These flanges serve as essential components in pipework systems, facilitating easy connection, disconnection, and flow control. Due to their robust characteristics, Alloy 20 Flanges find applications in industries such as chemical, pharmaceutical, food processing, and more.

Key Properties of Alloy 20 Flanges

The strength of Alloy 20 Flanges lies in their distinct chemical composition and metallurgical structure, which confer a host of advantageous properties:

• Excellent Corrosion Resistance: Alloy 20 Flanges exhibit remarkable resistance to sulfuric acid and other aggressive chemicals, making them suitable for chemical processing industries.

• Durability and Strength: With a high tensile strength, these flanges can withstand mechanical stresses and high-pressure environments.

• Resistance to Stress Corrosion Cracking: The addition of nickel minimizes the risk of stress corrosion cracking, especially in chloride environments.

• Good Fabricability and Weldability: The alloy can be easily formed and welded without compromising its mechanical properties.

• High Temperature Tolerance: Capable of withstanding elevated temperatures, Alloy 20 Flanges are ideal for heat-intensive processes.

Alloy 20 Flanges Specifications

For industries that require precise specifications, Alloy 20 Flanges meet stringent international standards. Here’s a look at the typical specifications:

• ASTM Standard: ASTM B 564 / ASME SB 564

• Dimension Standards: ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

• Size Range: 1/2″NB to 60″NB

• Pressure Ratings: 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64, etc.

• Flange Face Types: Flat Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

These specifications ensure that Alloy 20 Flanges can meet a wide range of industrial requirements, providing flexibility in usage across different applications.

Benefits of Alloy 20 Flanges

Choosing Alloy 20 Flanges comes with a host of advantages that make them a preferred choice for many industries:

1. Superior Corrosion Resistance: Ideal for environments where acids and chemicals are prevalent, ensuring long-term reliability and reduced maintenance costs.

2. Versatility Across Applications: Suitable for a variety of industries, from chemical and petrochemical to pharmaceutical and food processing.

3. High-Pressure Capability: With a range of pressure ratings, Alloy 20 Flanges can handle both high and low-pressure applications effectively.

4. Cost-Effective: Despite their high initial cost, the longevity and durability of Alloy 20 Flanges make them a cost-effective solution in the long run.

5. Compatibility with Other Materials: Can be used with other piping materials, allowing for flexible installation and system integration.

Applications of Alloy 20 Flanges

The unique characteristics of Alloy 20 Flanges make them suitable for several critical applications, including:

• Chemical Processing: Ideal for handling sulfuric acid and other aggressive chemicals, commonly found in chemical plants.

• Food Processing: Approved for use in environments where acidic foods are processed, thanks to their resistance to corrosion and contamination.

• Pharmaceutical Industry: Used in systems requiring high purity, as they prevent leaching and ensure a sterile environment.

• Marine Applications: With excellent resistance to chloride-induced corrosion, they are perfect for seawater applications.

• Oil and Gas Industry: Utilized in pipelines and machinery exposed to harsh chemical conditions and high pressures.

Why Choose Sankalp Alloys Overseas for Alloy 20 Flanges?

When it comes to sourcing Alloy 20 Flanges, Sankalp Alloys Overseas stands out as a trusted partner. Here’s why they should be your go-to choice:

1. Experience and Expertise: With years of experience in the industry, Sankalp Alloys Overseas is known for its manufacturing excellence and expertise in delivering high-quality Alloy 20 Flanges.

2. Global Reach: As leading Alloy 20 Flanges manufacturers and exporters, they cater to clients both in India and abroad, ensuring prompt delivery and consistent product quality.

3. Comprehensive Stock: They maintain a vast inventory of flanges, ensuring availability and quick dispatch for urgent requirements.

4. Stringent Quality Control: All products undergo rigorous quality checks to meet international standards and exceed customer expectations.

5. Customized Solutions: Offering a wide range of specifications and pressure ratings, Sankalp Alloys Overseas can provide flanges tailored to meet your specific industrial needs.

Conclusion

Alloy 20 Flanges are indispensable components for industries that demand robust, corrosion-resistant, and durable materials. Their unique properties make them an optimal choice for handling aggressive chemicals, high temperatures, and high-pressure environments. When it comes to sourcing these premium flanges, Sankalp Alloys Overseas has earned a reputation for delivering quality, reliability, and excellent customer service.

Their expertise in manufacturing, exporting, and supplying Alloy 20 Flanges in India and internationally ensures that you get products that not only meet but exceed industry standards.

Sankalp Alloys Overseas is a well-known Manufacturers, Suppliers, stockists, and Exporters of qualitative Alloy 20 Flanges. This austenitic, niobium-stabilized alloy contains low carbon content and nickel. These Alloy 20 flanges are available in nickel, chromium, and iron chemical elements added with molybdenum and copper. The content addition of molybdenum and copper makes them more resistant to corrosion in environments containing citric acids, phosphoric acids, sulfuric acids, and chlorides.

Contact Details

For inquiries, quotes, or more information, reach out to Sankalp Alloys Overseas:

• Contact Number: +91-8828369483

• Email: [email protected]

• Website: www.sankalpalloys.com

With Sankalp Alloys Overseas, you’re choosing experience, quality, and trustworthiness. Let them be your partner in industrial success.