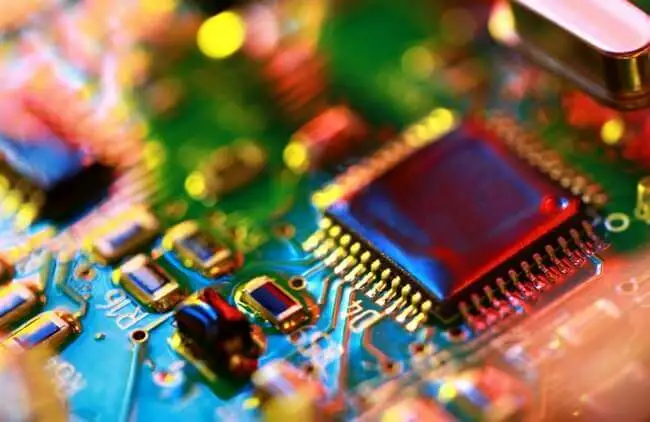

In an era of increasing environmental awareness and regulatory scrutiny, ROHS compliance testing has become a critical aspect of manufacturing electronics and electrical equipment. ROHS, or the Restriction of Hazardous Substances Directive, plays a pivotal role in promoting safety and sustainability by limiting the use of specific hazardous materials in electronic products. This article delves into the importance of ROHS compliance, the testing process, and how it impacts both manufacturers and consumers.

What is ROHS Compliance?

ROHS stands for the Restriction of Hazardous Substances, a directive that originated in the European Union and has been adopted by various countries around the world. The primary goal of ROHS is to reduce the environmental and health impacts of hazardous substances found in electronic and electrical equipment (EEE). The directive restricts the use of six specific substances:

- Lead (Pb): Often used in soldering materials, lead is harmful if ingested or inhaled and can cause neurological damage, particularly in children.

- Mercury (Hg): Used in some fluorescent lamps, mercury is toxic and can cause severe environmental contamination and health issues.

- Cadmium (Cd): Found in some batteries and pigments, cadmium is a carcinogen and can lead to kidney damage and bone loss.

- Hexavalent Chromium (Cr6+): Used in corrosion-resistant coatings, this substance is known for its carcinogenic properties and environmental impact.

- Polybrominated Biphenyls (PBBs): These flame retardants can accumulate in the environment and living organisms, posing health risks.

- Polybrominated Diphenyl Ethers (PBDEs): Similar to PBBs, PBDEs are used as flame retardants but can disrupt thyroid function and cause developmental issues.

By restricting these substances, ROHS aims to make electronic products safer for consumers and less harmful to the environment.

The Importance of ROHS Compliance Testing

ROHS compliance testing is essential for several reasons:

- Health and Safety: By ensuring that products do not contain hazardous substances, ROHS compliance helps protect consumer health. This is especially important as electronics are used in close contact with individuals and in various everyday applications.

- Environmental Protection: Reducing hazardous substances in electronics minimizes the environmental impact during manufacturing, use, and disposal. This contributes to lower levels of toxic waste and promotes recycling.

- Regulatory Compliance: Manufacturers must comply with ROHS regulations to sell products in many markets, particularly in the European Union. Non-compliance can result in fines, product recalls, and damage to the brand’s reputation.

- Market Access: ROHS compliance is often a prerequisite for entering international markets. Ensuring that products meet these standards can open up opportunities for global trade.

The ROHS Compliance Testing Process

Achieving ROHS compliance involves a detailed testing process to ensure that electronic products meet regulatory standards. Here’s a step-by-step overview of how ROHS compliance testing typically works:

- Pre-Test Preparation: Manufacturers begin by identifying and documenting all materials and components used in their products. This includes reviewing material safety data sheets (MSDS) and supplier information to understand the composition of each part.

- Sample Selection: The next step is selecting representative samples from the production batch. It’s important to choose samples that accurately reflect the product’s composition and manufacturing process.

- Laboratory Analysis: Samples are sent to a specialized ROHS testing laboratory where they undergo analysis using various techniques. Common methods include:

- X-Ray Fluorescence (XRF): A non-destructive technique used to detect and quantify the presence of restricted substances. XRF provides rapid and accurate results for screening purposes.

- Inductively Coupled Plasma Mass Spectrometry (ICP-MS): This technique is used for detecting trace amounts of heavy metals and other elements. It offers high sensitivity and accuracy for determining compliance with ROHS limits.

- Fourier Transform Infrared Spectroscopy (FTIR): This method helps identify organic compounds and verify the absence of restricted flame retardants.

- Data Analysis and Reporting: The laboratory analyzes the data and generates a compliance report. This report details the levels of restricted substances found in the samples and confirms whether the product meets ROHS standards.

- Certification and Documentation: If a product passes the testing, the manufacturer receives a certificate of compliance. This documentation is essential for regulatory submissions and market approvals. Manufacturers must keep detailed records to demonstrate ongoing compliance.

- Post-Market Surveillance: Even after achieving initial compliance, manufacturers must monitor and ensure that products continue to meet ROHS requirements throughout their lifecycle. This includes periodic testing and reviews as regulations evolve.

The Impact of ROHS Compliance

ROHS compliance has a profound impact on various stakeholders:

- Manufacturers: Compliance helps avoid costly penalties and recalls while improving product quality and marketability. It also demonstrates a commitment to environmental responsibility, enhancing the brand’s reputation.

- Consumers: For consumers, ROHS compliance translates into safer products that do not pose health risks. It also ensures that the electronics they use are less harmful to the environment.

- The Environment: By reducing the presence of hazardous substances, ROHS compliance contributes to a healthier environment. It supports recycling efforts and reduces the impact of electronic waste.

Future Trends and Challenges

As technology evolves, new substances and materials may emerge that require regulation. The ROHS directive is periodically updated to address these changes and expand its scope. Manufacturers must stay informed about regulatory updates and adapt their processes accordingly to maintain compliance.

Additionally, advancements in material science and electronics may introduce new challenges in testing and compliance. Innovations in green chemistry and sustainable materials will play a crucial role in shaping the future of ROHS compliance.

Conclusion

ROHS compliance testing is a vital component of ensuring that electronic products are safe for consumers and environmentally friendly. By understanding and adhering to ROHS regulations, manufacturers can protect public health, meet regulatory requirements, and contribute to a more sustainable future. For accurate testing and reliable compliance certification, it is essential to work with experienced laboratories that specialize in ROHS testing. This commitment to safety and sustainability not only enhances product quality but also builds trust with consumers and partners in the global marketplace.

For more information on ROHS compliance testing and how to ensure your products meet the highest standards, visit our ROHS compliance testing page today. Let us help you navigate the complexities of ROHS regulations and achieve compliance with confidence.