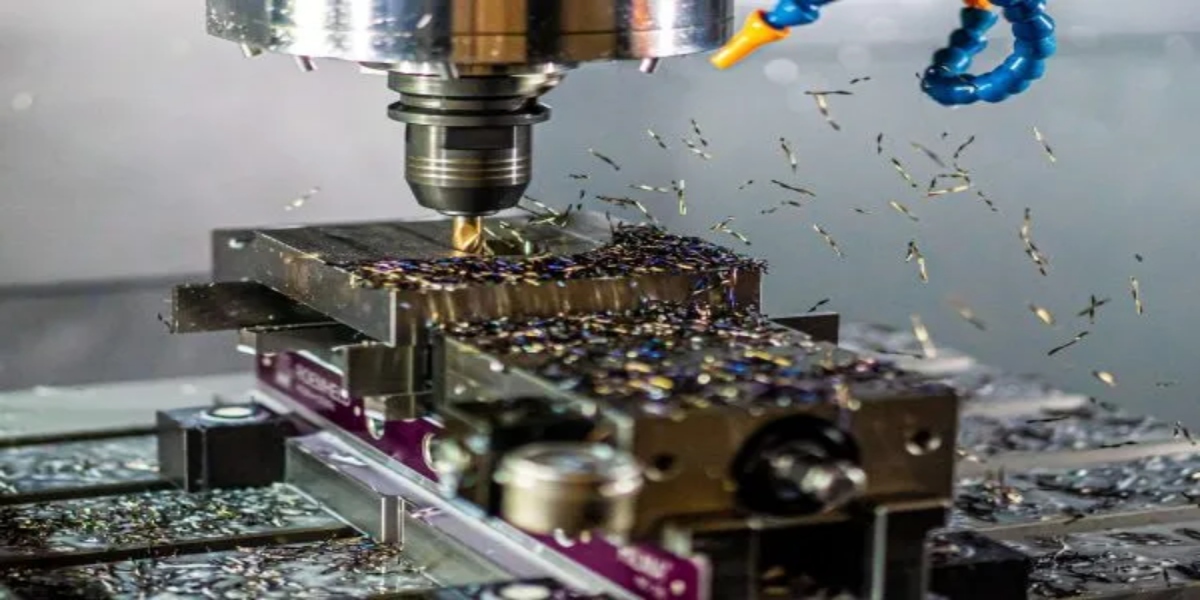

Selecting the right materials for CNC (Computer Numerical Control) machining is a critical step in the manufacturing process, especially in a hub like Melbourne, Australia, known for its robust manufacturing sector. CNC machining offers precision and flexibility for creating complex parts. However, the success of this process greatly depends on choosing the appropriate materials. Below are essential considerations to keep in mind when selecting materials for CNC machining, ensuring that your manufacturing project meets the desired standards of quality and efficiency.

1. Understand the Material Properties

The choice of material for CNC machining should be guided by the specific properties you need in the finished product. These properties include:

- Strength and Durability: Metals like aluminium and stainless steel provide excellent strength and are suitable for parts requiring high durability.

- Heat Resistance: For components that will experience high temperatures, materials such as titanium and brass are ideal due to their high melting points.

- Corrosion Resistance: If the part is likely to encounter corrosive conditions, consider corrosion-resistant materials like stainless steel or certain plastics.

- Machinability: Some materials are more machinable than others, affecting the speed and cost of the manufacturing process. Aluminium is notably easy to machine, while harder materials like hardened steel might require more time and specialised machinery.

2. Consider the Application of the Part

The intended use of the manufactured part plays a pivotal role in material selection. For aerospace components, lightweight materials such as titanium might be preferred. In contrast, for automotive parts, you might choose materials like aluminium for its excellent balance between weight and strength.

3. Factor in the Complexity of the Design

The complexity of the design also influences material choice. Materials that allow for high-precision machining and fine detailing without compromising the structural integrity are preferable. CNC machining offers the flexibility to handle both metals and plastics,enabling manufacturers to achieve intricate designs that other methods might not support.

4. Budget Constraints

Cost is a significant factor in material selection. Materials vary not only in performance but also in price. For example, titanium offers outstanding benefits but at a higher cost compared to materials like aluminium. Balancing cost and performance requirements is crucial, particularly in competitive markets like Melbourne, where efficiency and cost-effectiveness are key.

5. Environmental Considerations

Environmental impact is increasingly becoming a consideration in manufacturing. Materials that are recyclable and eco-friendly are gaining popularity. In Melbourne, where sustainability is taken seriously, choosing materials that align with these values can also align with local business practises and regulations.

6. Availability of Materials

Local availability of materials can significantly affect the choice of material for CNC machining. In Melbourne, where there is a well-established network of material suppliers, manufacturers have a variety of options. However, it’s essential to consider the supply chain and potential delays in material delivery, which can impact the overall timeline of the manufacturing process.

7. Compliance with Industry Standards

Materials used in CNC machining must often meet specific industry standards, especially in sectors like aerospace, medical, and automotive. Compliance ensures not only the safety and reliability of the CNC parts but also conformity with global market standards, which is critical for products exported from Australia.

8. Testing and Prototyping

Before finalising the material for the full production run, testing and prototyping are advisable. This step allows manufacturers to verify that the chosen material meets all the required specifications and performance criteria under realistic conditions.

9. Expert Consultation

Consulting with CNC machining experts can provide valuable insights, particularly when you’re faced with a challenging decision regarding material selection. In Melbourne, where there is a thriving community of manufacturing professionals, leveraging local expertise can help tailor your material choice to your specific CNC manufacturing needs.

Choosing the appropriate material for CNC machining is a complex decision that demands a thorough knowledge of material properties, application requirements, design complexities, and budget constraints. In Melbourne’s competitive CNC metal machining industry, making informed material choices is vital for maintaining quality, efficiency, and market relevance. By considering these key factors, manufacturers can ensure that they choose the most suitable materials for their CNC projects, leading to successful outcomes in their manufacturing endeavors.